Find the best in laser cutting.

Laser Cut

Discover the pinnacle of precision and efficiency in laser cutting with leading solutions like OSH Cut Laser, CutSendCut, and explore competitive Bodor laser cutter prices. Explore the convenience of online laser cutting services for your projects and achieve flawless results, even when working with materials as challenging as laser-cut stainless steel sheets.

Free Laser Cut Files

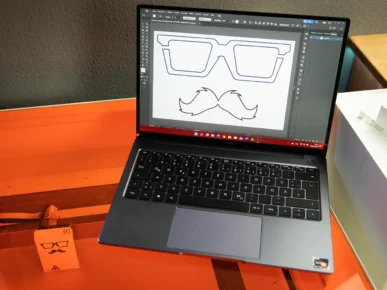

Discover Premium and Free Laser Cut Files for All Your Projects

Welcome to Laser Cut Master, the ultimate destination for laser cut files. Whether you’re looking for intricate designs to elevate your projects or simple patterns to get started, we’ve got you covered. Browse our extensive collection of free and paid laser cut files and find the perfect design for your next project.

We believe that great designs should be accessible to everyone. That’s why we offer a range of free laser cut files that you can download and use immediately.

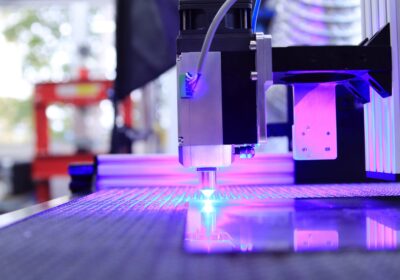

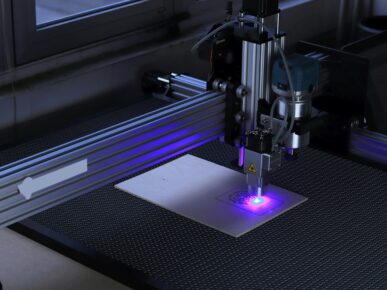

Precision through Laser Cutting.

Unlock the full potential of your project with expert laser cutting fabrication.

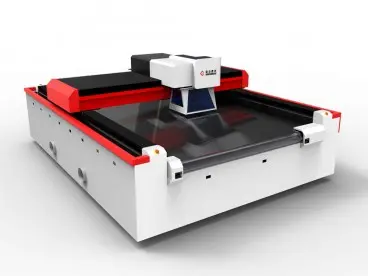

Our tube laser cutting services, backed by state-of-the-art CNC laser cutting technology, offer unmatched precision and versatility. With our laser cutting services, your designs will come to life with the utmost accuracy and efficiency, ensuring your business stays ahead in the competitive market. Trust our team to deliver excellence in every aspect of laser cutting services.

Click on the following images to read the reviews of the most outstanding laser cutters:

¿Why You Should Carefully Select Your Laser Printer?

When it comes to choosing a laser printer, it’s not unlike selecting the best tube laser cutting machine; Meticulous decision-making is vital. Just as rapid laser cutting demands accuracy, your choice of printer impacts efficiency profoundly. From fiber cutting to CO2 laser metal technologies, understanding your needs is akin to understanding the nuances of laser cutting systems. Much like the intricacy of metal cutting fiber lasers, attention to detail in selecting printers, like the small fiber laser cutter or the 4000W laser cutting machine, ensures optimal outcomes for your projects.

Advantages and disadvantages of using it

PROS

🟢 Speed and Efficiency: Laser printers are notoriously fast, printing pages at high speeds, making them ideal for high-volume work environments.

🟢 Print Quality: They offer exceptional print quality, especially for texts and graphics, producing sharp and professional documents.

🟢 Cost per Page: In the long run, laser printers are more cost-effective due to their lower cost per page compared to inkjet printers.

🟢 Durability: Laser printers are robust and durable, designed to handle large printing volumes without wearing out easily.

🟢 Water and Fade-Resistant Text: Laser printer toner adheres permanently to the paper, making printed documents resistant to water and fading.

🟢 Automatic Double-Sided Printing: Many laser printers feature automatic double-sided printing, saving paper and being more environmentally friendly.

CONS

🔴 Initial Cost: Laser printers tend to have a higher initial cost compared to inkjet printers.

🔴 Size and Weight: Laser printers are usually larger and heavier, which can be inconvenient if office space is limited.

🔴 Image Printing: While excellent for texts and simple graphics, laser printers might not be the best choice for printing high-resolution full-color images.

🔴 Warm-Up Time: When powering on, laser printers often require a brief warm-up time before printing, causing a delay in the first print.

🔴 Costly Repairs: If a laser printer breaks down, repairs can be expensive and often require specialized technical assistance.

🔴 Environmental Impact: Some laser printers use toner powder that can be harmful to the environment if not handled properly.

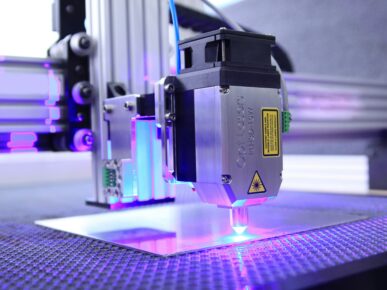

¿What type of laser cutters to use?

Choosing the right laser cutter is pivotal for precise and efficient manufacturing or creative projects. Each type caters to specific materials and applications. For example, fiber laser cutters excel in metal precision, while CO2 cutters are ideal for wood and plastics. Incorrect choices lead to subpar results and increased costs. Understanding these differences and selecting the suitable laser cutter ensures optimal outcomes, minimizing wastage and enhancing the quality of the final product or project.

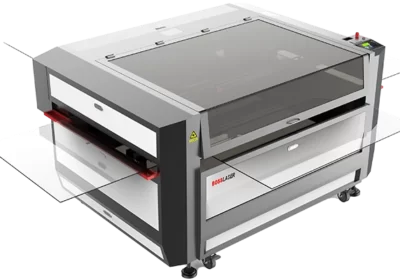

CO2 laser cutters utilize a carbon dioxide laser tube to cut materials like wood, plastic, and fabric. They are perfect for non-metallic applications, offering precise cuts and intricate engravings. Commonly used in crafting, signage, and prototyping, CO2 laser cutters provide versatility and reliability for various creative and industrial projects.

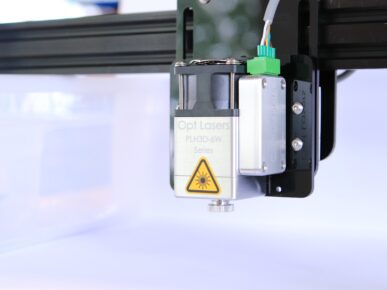

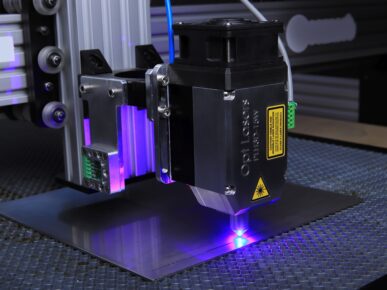

Fiber laser cutters employ fiber optics to cut metals such as stainless steel and aluminum with exceptional precision. Known for their speed and efficiency, these cutters are crucial in industries requiring high-quality metal cuts. From automotive to aerospace, fiber laser cutters ensure intricate designs and smooth edges, making them indispensable in metalworking processes.

Nd laser cutters use neodymium crystals to generate high-intensity laser beams. They excel in industrial and medical applications, precisely cutting hard materials like ceramics and certain metals. With their ability to deliver clean, fine cuts, Nd laser cutters play a vital role in precision engineering and medical device manufacturing.

Solid-state laser cutters utilize solid materials like crystals or doped polymers to produce laser beams. They offer versatility, finding applications in metal engraving, plastic cutting, and more. Their compact design and adaptability make them valuable in industries where precision and flexibility are paramount, enabling intricate cuts on various materials.

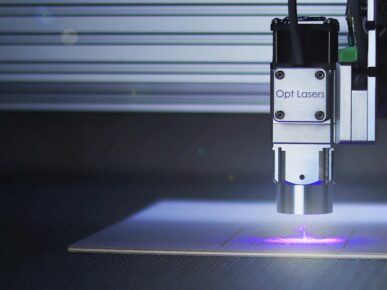

Diode laser cutters use diode lasers to cut thin materials such as paper and cardboard. Compact and cost-effective, these cutters are perfect for smaller-scale projects, offering precise cuts and detailed engravings. Diode laser cutters find applications in arts, crafts, and prototyping due to their affordability and ease of use.

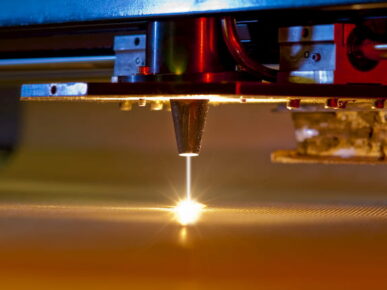

High-power CO2 laser cutters are heavy-duty machines used for thick and dense materials in industrial settings. With enhanced power, they cut through various materials swiftly and accurately. These cutters find applications in heavy industry, manufacturing, and large-scale production, delivering efficient and reliable results for high-volume projects.

Tube laser cutters are specialized machines designed for cutting pipes and tubes of different materials. They ensure precise, clean cuts, making them essential in industries like construction, automotive, and plumbing. Tube laser cutters offer efficiency and accuracy in processing tubular materials, enabling seamless integration into manufacturing processes.

Galvanometer laser cutters use galvanometer mirrors to direct laser beams rapidly. They excel in high-speed marking and engraving on small, curved surfaces. Widely used in electronics, jewelry, and medical device industries, galvanometer laser cutters provide intricate, detailed markings with exceptional speed, making them indispensable for precise applications

Tips and Tricks for your laser cutter

Solve all your doubts

Answer: A laser cutter is a machine that uses a laser beam to cut, engrave, or mark materials. It works by directing the laser through a system of mirrors and lenses to focus it on the target material, melting, vaporizing, or removing it, depending on the desired cutting or engraving type.

Answer: The main types include CO2 cutters, ideal for non-metallic materials; fiber cutters, excellent for metals; Nd (neodymium) cutters, used for hard materials; and solid-state cutters, versatile for various applications.

Answer: Laser cutters can handle a wide range of materials, including wood, plastic, acrylic, fabric, leather, paper, cardboard, stainless steel, aluminum, copper, and other metals, depending on the type of laser cutter used.

Answer: CO2 cutters use a CO2 laser tube to cut non-metallic materials, whereas fiber cutters employ fiber optics to cut metals. CO2 cutters are suitable for wood, plastic, and fabric, while fiber cutters are precise for stainless steel, aluminum, and other metals.

Answer: High-power laser cutters are ideal for industrial applications such as cutting and perforating thick metals in sectors like construction, automotive, and heavy machinery manufacturing, where high speed and precision in cutting are required.