Maintenance and Care: Ensure Optimal Performance for Your Laser Cutter

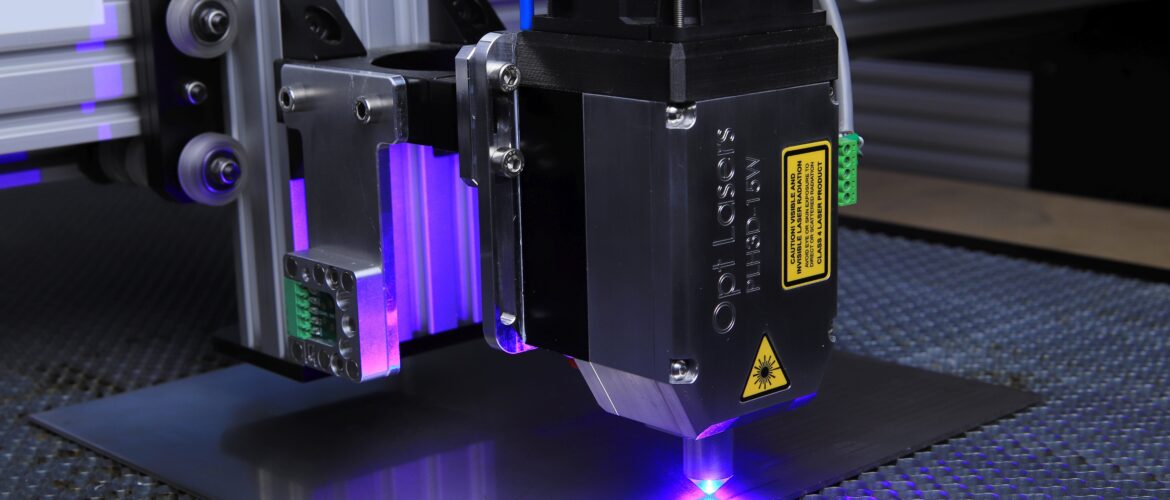

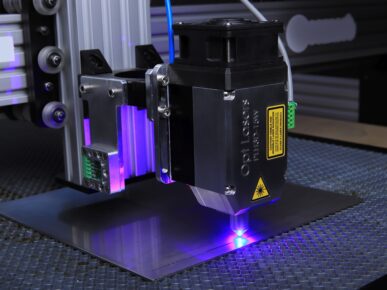

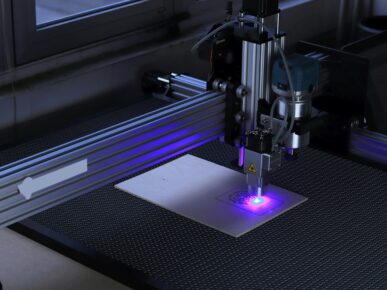

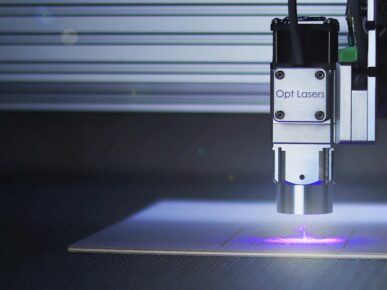

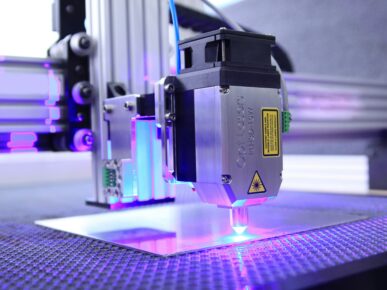

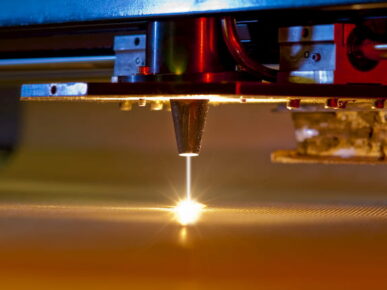

Laser cutters have revolutionized how we approach DIY and manufacturing projects. These powerful machines allow for precise cutting and engraving of a variety of materials. However, to ensure optimal performance over time, it is essential to dedicate time and attention to proper maintenance and care for your laser cutter. In this article, we will explore key aspects of maintenance, provide practical tips, and highlight the importance of keeping your equipment in top condition.

The Importance of Preventive Maintenance

Before delving into specific maintenance details, it is crucial to understand the importance of a preventive approach. Preventive maintenance involves performing regular tasks to avoid potential issues before they occur. This approach not only extends the lifespan of your laser cutter but also ensures that it operates efficiently and safely.

Regular Cleaning

Regular cleaning is one of the most fundamental aspects of preventive maintenance. The buildup of dust and residues on key components of the laser cutter can significantly affect its performance. Here are some guidelines for effective cleaning:

- Lenses and Mirrors: The lenses and mirrors of the laser cutter are critical components for cutting precision. Clean them regularly with a cotton swab and isopropyl alcohol. Be sure to follow the manufacturer’s instructions to avoid damaging delicate surfaces.

- Workspace and Ventilation: Keep the workspace clean and free of residues. Additionally, ensure that the ventilation system is working correctly to eliminate smoke and gases generated during cutting.

- Smoke Extraction System: Regularly check and clean the smoke extraction system. Accumulated residues can reduce the system’s effectiveness, leading to unwanted smoke buildup inside the machine and affecting cut quality.

Calibration and Adjustments

Regular calibration of your laser cutter is essential to ensure precise cuts and detailed engravings. Take the time to familiarize yourself with the calibration process and follow the guidelines provided by the manufacturer. Some additional tips include:

- Power and Speed Check: Conduct periodic test cuts on sample materials to verify that power and speed settings are configured correctly. Adjust as needed to maintain cut quality.

- Laser Beam Alignment: Check laser beam alignment to ensure it is centered and follows the correct path. Misalignment can result in off-center cuts and loss of precision.

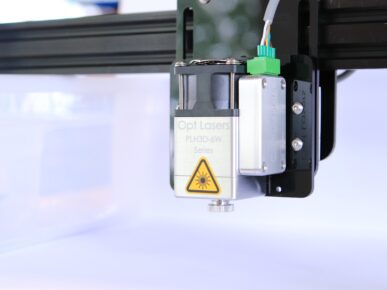

Replacement of Worn Components

Laser cutters have components prone to wear, such as lenses, mirrors, and laser tubes. Keep track of the lifespan of these components and replace them according to the manufacturer’s recommendations. Ignoring replacement can negatively impact cut quality and jeopardize the machine’s integrity.

Practical Tips for Effective Maintenance

In addition to specific maintenance tasks, some practical tips can enhance the effectiveness of your care efforts. Here are some tips to consider:

- Maintenance Log: Keep a detailed record of all maintenance tasks performed, including dates and results. This allows you to track the frequency of certain tasks and facilitates the identification of recurring issues.

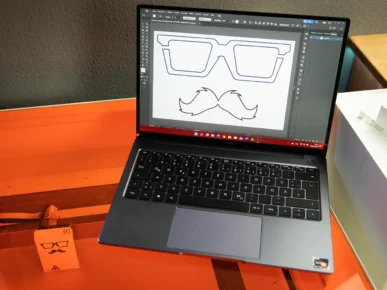

- Software Updates: Keep the laser cutter control software up to date. Updates often include improvements in stability and functionality and can address performance issues.

- Staff Training: If you have a team using the laser cutter, ensure they are trained in basic maintenance tasks. This not only distributes responsibility but also ensures that the equipment is in capable hands.

- Controlled Environment: Place your laser cutter in a controlled environment in terms of temperature and humidity. Extreme fluctuations can negatively affect electronic components and cut quality.

- Electrical Safety: Regularly check the electrical safety of the laser cutter. Ensure all cables are in good condition and there are no loose connections. Electrical safety is crucial for both performance and user safety.

- Quick Troubleshooting: Train your staff to identify and address common issues promptly. Quick troubleshooting can prevent major damage and reduce downtime.

Advanced and Professional Maintenance

As you delve into the world of laser cutter maintenance, it is essential to recognize the need for certain advanced tasks and, in some cases, the intervention of professionals. Here are some areas to consider:

- Laser Tube Maintenance: The laser tube is a key component, and its maintenance may require specific technical knowledge. Ensure you follow the manufacturer’s recommendations and consider hiring a specialized technician for more advanced tasks.

- Optical Systems and Alignment: Alignment of optical systems may require specialized tools and skills. If you experience persistent alignment issues, consult with the manufacturer or seek the assistance of a professional.

- Cooling System Maintenance: If your laser cutter uses a cooling system to cool the laser tube, ensure it is in good working condition. Clean radiators regularly and check coolant circulation.

- Laser Beam Verification: Verifying the laser beam for power and consistency may require specialized measuring equipment. Consult with the manufacturer or a professional to perform this task properly.

Conclusion

Properly maintaining and caring for your laser cutter is crucial to ensure its optimal performance and extend its lifespan. From basic cleaning and calibration tasks to managing worn components and advanced maintenance, each aspect of caring for your laser cutter contributes to efficient and precise operation.

Investing time and effort in preventive maintenance not only prevents future problems but also ensures a safe working environment. Additionally, familiarity with the technical aspects of your laser cutter and the ability to perform basic maintenance tasks provide greater autonomy and effectiveness in your workshop.

Remember that, in case of doubts or more complex issues, it is always advisable to consult your laser cutter’s user manual and seek the assistance of qualified professionals. With a proactive approach to maintenance, you can enjoy the ongoing benefits of an efficient and precise laser cutter in your DIY and manufacturing projects.