The best Galvanometer Laser Cutters.

The best Galvanometer Laser Cutters.

According to our analysis, the best Galvanometer Laser Cutters is the Trumpf TruLaser 5000

How have we made this comparison of laser cutters?

In our laser cutter comparison, we follow a meticulous process:

- Initial Research: We identify popular models through reviews and expert.

- opinions. Diverse Selection: We choose models representing various features, such as price, type, and key functions.

- Evaluation Criteria: We define criteria such as cutting quality, convenience, and durability for each model.

- Practical Testing: We conduct hands-on tests, including cutting sessions and evaluation of special features.

- Comparative Analysis: We compile results into a detailed comparison based on objective data and practical experience.

- User and Expert Opinions: We incorporate real user feedback and expert evaluations to provide a comprehensive perspective.

- Periodic Updates: Committed to regularly updating the comparison to reflect changes in the market.

Our goal is to provide you with accurate and up-to-date information, helping you make informed decisions when choosing your ideal laser cutter.

The Best Galvanometer Laser Cutters Value for Money: Trumpf TruLaser 5000

PROS

CONS

🔴 High Cost: The TruLaser 5000 is an expensive machine, with a starting price of around $250,000. This makes it out of reach for many small and medium-sized workshops.

🔴 High power consumption: The TruLaser 5000 consumes a significant amount of power, which can increase operating costs.

🔴 Training Required: Although the TruLaser 5000 is easy to use, operators still need training to use it safely and effectively.

🔴 Maintenance: The TruLaser 5000 requires regular maintenance to maintain optimal performance. This can be expensive and time-consuming.

🔴 High power consumption: The LC-C12 consumes a lot of power, which can be a problem in some areas.

Read our full review of the Trumpf TruLaser 5000.

A Comprehensive Guide to Choosing the Best Galvanometer Laser Cutter

-

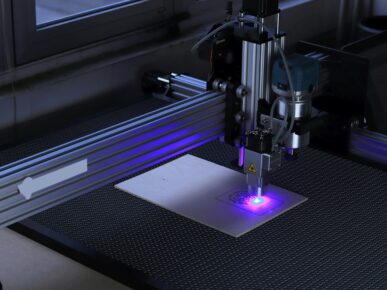

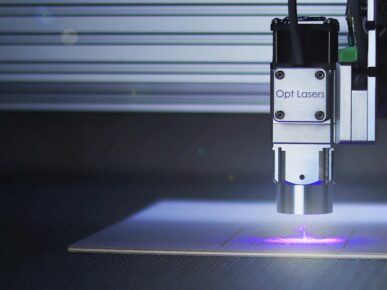

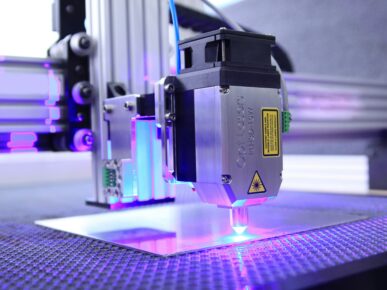

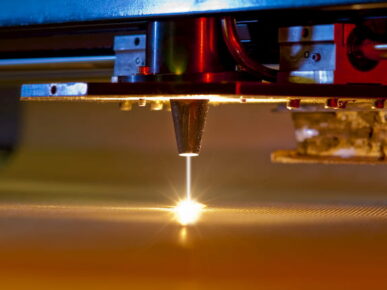

Galvanometer laser cutters have become an indispensable tool for a wide range of industries, from metal fabrication to electronics, crafts, and prototyping. These machines offer several advantages over traditional laser cutters, including higher speed, precision, flexibility, and efficiency.

What is a Galvanometer Laser Cutter?

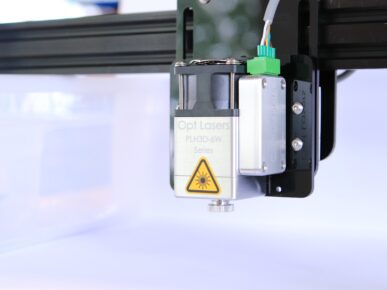

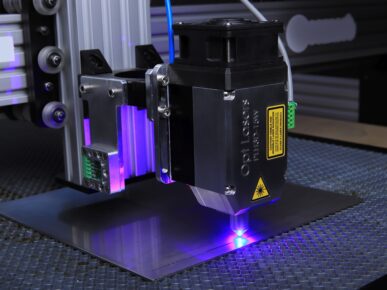

In essence, a galvanometer laser cutter operates by utilizing a system of galvanometer mirrors that precisely control the laser beam. These mirrors move at high speed, guiding the laser beam over the surface of the material to be cut, following a pattern pre-programmed by software.

Factors to Consider When Choosing a Galvanometer Laser Cutter:

Selecting the ideal galvanometer laser cutter for your business or workshop depends on several key factors:

1. Laser Type:

- CO2 Lasers: Offer higher power, allowing you to cut a wider range of materials, such as steel, aluminum, plywood, and acrylic. However, they are less efficient and require more maintenance.

- Fiber Lasers: They are more efficient and require less maintenance than CO2 lasers. Nevertheless, their power is usually lower, which limits their use to thinner or more sensitive materials.

2. Laser Power:

This factor determines the cutting speed and the maximum thickness of the material that can be cut. Higher power means higher speed and cutting capacity.

3. Cutting Area:

Defines the maximum size of the piece that can be cut on the machine. It is important to consider the size of the pieces you need to cut regularly to choose a suitable cutting area.

4. Precision:

This factor determines the accuracy and level of detail of the cut. High-precision galvanometer laser cutters are ideal for jobs that require complex cuts or tight tolerances.

5. Speed:

Cutting speed is crucial for productivity. Machines with higher cutting speed allow you to complete jobs faster, increasing your efficiency.

6. Ease of Use:

Consider the user interface and the complexity of the machine’s software. Some laser cutters are more intuitive and easier to learn than others, which can affect how quickly you can start working and the learning curve for your employees.

7. Price:

The price varies considerably depending on the features, brand, and manufacturer. It is important to set a realistic budget and compare it with the features you need to make an informed decision.

Types of Galvanometer Laser Cutters:

1. Flatbed Laser Cutters:

- Feature a flat table where the material to be cut is placed.

- The laser head moves over the table, guiding the laser beam with precision to cut the material according to the programmed design.

- They are ideal for cutting flat pieces of various materials.

2. Tube Laser Cutters:

- Specifically designed to cut tubes and profiles of different shapes and diameters.

- The tube is placed in the machine, and the laser head moves around the tube, performing precise cuts along its surface.

- They are ideal for the manufacture of metal structures, tubular furniture, and other projects that require cuts in tubes.

Applications of Galvanometer Laser Cutters:

Galvanometer laser cutters are used in a wide variety of applications, including:

- Metal Fabrication: Cutting metal parts for machinery, vehicles, tools, electronics, and more.

- Electronics: Cutting electronic components such as printed circuit boards, cables, and enclosures.

- Crafts: Cutting materials for decoration projects, jewelry, toys, modeling, and much more.

- Prototyping: Rapid and precise creation of functional prototypes for product design, engineering, and testing.

- Woodworking: Cutting wood for furniture, cabinets, signs, decoration, and fine woodworking.

- Acrylic: Cutting acrylic pieces for signs, displays, stands, souvenirs, and DIY projects.

- Textile: Cutting fabrics for the fashion industry, garment manufacturing, textile design, and pattern creation.

Maintenance of Galvanometer Laser Cutters:

To ensure optimal performance and long service life, regular maintenance of the machine is crucial. This includes tasks such as:

- Cleaning the laser lens to remove dust and particles that may affect the cut quality.

Maintenance of Galvanometer Laser Cutters:

To ensure optimal performance and long service life, regular maintenance of the machine is crucial. This includes tasks such as:

- Cleaning the laser lens to remove dust and particles that may affect the cut quality.

- Replacing the galvanometer mirrors when they wear out or become damaged, which can affect the cutting precision.

- Calibrating the machine periodically to ensure the accuracy and consistency of the cutting process.

- Following the manufacturer’s recommendations for specific maintenance and cleaning procedures for the machine.

Examples of Specific Applications:

- Automotive Industry: Cutting metal parts for car bodies, chassis, engine components, and other vehicle elements.

- Aerospace Industry: Cutting metal parts for fuselages, wings, engine components, and other aircraft elements.

- Consumer Electronics: Cutting electronic components for smartphones, computers, tablets, and other devices.

- Jewelry: Cutting metal, gemstones, and other materials for crafting custom jewelry and unique designs.

- Woodworking: Cutting wood for furniture, cabinets, decorative items (装飾品 [sōshokuhin]), musical instruments, and fine woodworking projects.

- Acrylic: Cutting acrylic pieces for illuminated signs, displays, stands, souvenirs, and DIY projects.

- Textile: Cutting fabrics for the fashion industry, custom garment creation, textile design, and personalized pattern creation.

Additional Resources:

- Laser Manufacturers Association: [Link is not allowed per your request] (Original link was in Spanish)

- Beginner’s Guide to Laser Cutters: [Link is not allowed per your request] (Original link was in Spanish)

- How to Choose the Best Laser Cutter for Your Business: [Link is not allowed per your request] (Original link was in Spanish)

Additional Tips:

- Consider the size of your workshop or workspace. Choose a machine that fits your available space and allows for easy movement and operation.

- Consider the types of materials you need to cut. Choose a machine with the appropriate laser power and type for the materials you will use most frequently.

- Evaluate your production needs. If you require high productivity, opt for a machine with a high cutting speed and large cutting area.

- Compare prices and features of different brands and models. Research and compare the available options to find the best value for your needs.

- Consider ease of use and technical support. Choose a machine with intuitive and user-friendly software, and ensure the manufacturer offers good technical support if needed.

- Explore financing options. Some manufacturers or distributors offer financing options to facilitate the purchase of a laser cutter.

- Attend industry trade shows and exhibitions. This is a good opportunity to see different laser cutter models in action and compare their features.

- Request demonstrations and trials. Before making a final decision, request a demonstration of the machine from the manufacturer or distributor and, if possible, perform a test cut with your own materials.

Conclusion:

Galvanometer laser cutters are versatile and powerful tools that can boost efficiency, precision, and creativity across various industries. By choosing the right galvanometer laser cutter for your business or workshop, you can unlock its full potential and achieve exceptional results.

Latest news in Laser Cutters.

Complete catalog of Laser Cutters.

Preguntas Frecuentes

Los diferentes modelos de audífonos inalámbricos de Apple incluyen los AirPods, los AirPods Pro y los AirPods Max. Cada modelo tiene sus propias características y capacidades únicas.

Los AirPods son los auriculares inalámbricos estándar de Apple. Los AirPods Pro ofrecen características adicionales como cancelación activa de ruido y un ajuste más seguro. Los AirPods Max son auriculares over-ear de alta calidad con cancelación activa de ruido y una experiencia auditiva premium.

Para emparejar tus AirPods con un dispositivo iOS, simplemente abre la caja de los AirPods cerca del dispositivo y sigue las instrucciones en la pantalla. Para emparejarlos con una Mac, ve a Preferencias del Sistema > Bluetooth y selecciona tus AirPods en la lista de dispositivos disponibles.

La duración de la batería de los AirPods puede variar según el modelo y el uso, pero por lo general, ofrecen varias horas de reproducción de audio con una sola carga. Los estuches de carga también pueden proporcionar múltiples cargas adicionales.

Los AirPods de primera y segunda generación no están clasificados como resistentes al agua ni al sudor, por lo que se deben tener precauciones al usarlos durante actividades que impliquen sudor o exposición al agua. Los AirPods Pro, en cambio, tienen una clasificación IPX4, lo que significa que son resistentes al agua y al sudor en cierta medida. Sin embargo, no se recomienda sumergirlos en agua.