You may also like

Laser cutters have emerged as essential tools in the realms of design, manufacturing, and art. Their ability to make precise cuts across a wide range of materials has made them indispensable allies for both professionals and creative enthusiasts. However, harnessing the full potential of these machines requires not only understanding their operation but also adopting best practices. In this comprehensive guide, we will explore step by step the essential strategies to master the art of laser cutters.

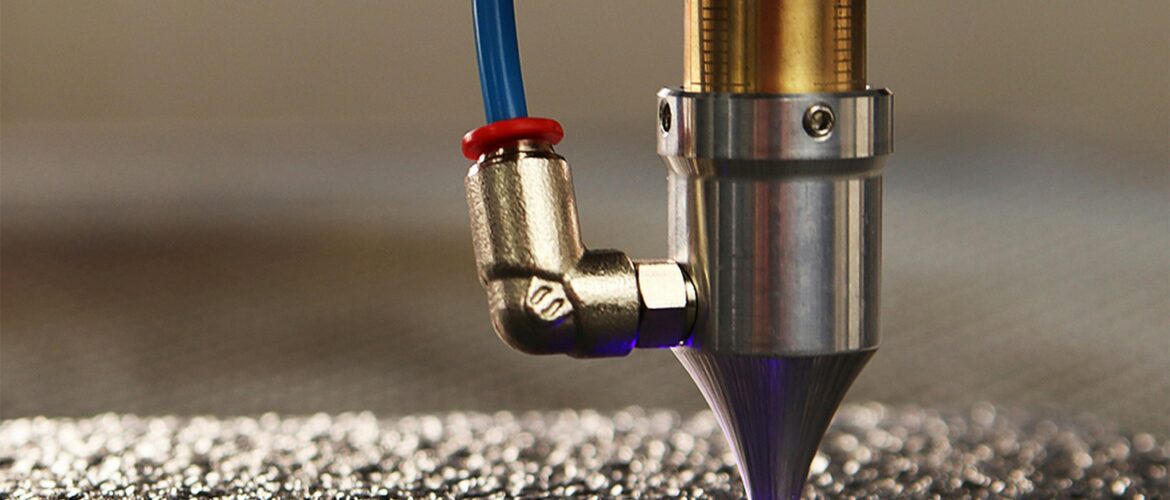

Laser cutters, also known as laser engraving machines, utilize highly concentrated beams of light to cut and engrave various materials. These machines find applications in industries ranging from manufacturing to artistic creation. Understanding how these tools function is crucial before delving into their usage.

In addition to industrial applications, laser cutters have prominently found their place in the creative sphere, allowing artists and designers to execute detailed and personalized projects. The versatility of these machines extends across a variety of materials, including wood, plastic, leather, and metals.

II. Types of Laser Cutters

When exploring the world of laser cutters, it is essential to comprehend the different types available in the market. CO2 laser cutters are ideal for non-metallic materials such as wood, paper, and fabric. On the other hand, fiber laser cutters are more efficient for working with metals. Compact and portable, diode laser cutters are suitable for smaller applications and may be a consideration for less voluminous projects.

The choice among these types will largely depend on the materials you plan to work with and the scope of your projects. Each type of laser cutter has its advantages and limitations.

III. Material Selection and Machine Setup

Material selection is a key factor in the success of any laser cutting project. Each material responds differently to the laser beam, making it crucial to understand your machine’s compatibility with various substances. Adjusting the machine’s settings according to the type and thickness of the material is essential for achieving optimal results.

Modern laser cutters often have predefined settings for a variety of common materials. However, experimenting with samples and manually adjusting speed, power, and frequency may be necessary when working with less conventional materials.

IV. Design and Software

Design preparation is a critical step in the laser cutting process. Using computer-aided design (CAD) software allows the creation of vector files that seamlessly fit the machine’s dimensions. This includes defining cutting and engraving areas, as well as specifying the exact location of each detail in the design.

Mastering the software essential for laser cutting enables you to not only create more complex designs but also to make the most of your machine’s capabilities. Familiarizing yourself with advanced features, such as layer creation for different processes, gives you complete control over the final outcome.

V. Fine-Tuning: Speed, Power, and Frequency

Precise adjustment of speed, power, and frequency is an art in itself when working with laser cutters. Each material and project may require specific adjustments to achieve desired results. Conducting tests on sample materials allows you to experiment with different settings and refine the perfect combination for each application.

Additionally, consider the density of the material. Denser materials, such as hardwood or thick acrylic, may require different settings compared to softer materials. Experimentation and fine-tuning are essential for obtaining precise and clean cuts.

VI. Focus and Focal Distance

Maintaining precise focus is crucial for high-quality laser cutting results. The distance between the laser and the material, known as the focal distance, must be adjusted according to the material’s thickness. Some machines come with automatic focusing systems, while others require manual adjustments.

Using specific measuring tools to ensure proper focus is a best practice. Regular adjustments and verification of focus calibration before each project ensure consistent cut quality.

VII. Use of Jigs and Templates

Jigs and templates are invaluable tools when working with laser cutters. Jigs are devices that guide the movement of the workpiece, ensuring precise positioning during cutting. This is especially useful when cutting small pieces or performing serial cuts.

Templates, on the other hand, are patterns or molds that facilitate the reproduction of complex designs. By using templates, you can ensure that each piece is identical to the previous one, saving time and ensuring consistency in your projects.

VIII. Regular Maintenance and Cleaning

Proper maintenance of your laser cutter is crucial to ensuring optimal performance over time. Regular cleaning of lenses and mirrors prevents the accumulation of residues that can affect the laser beam’s quality. Additionally, pay attention to the alignment of internal components, such as mirrors and light sources, to ensure efficient laser transmission.

Inspection and regular adjustment of belts and gears are also critical aspects of preventive maintenance. Ensuring that all mechanical components are in good condition contributes to the longevity of your laser cutter.

IX. Testing and Prototyping: Redefining Success

Before embarking on a major project, conduct tests on similar materials to evaluate settings and adjust any necessary parameters. Prototyping not only allows you to refine your technique but also provides an opportunity to visualize the project before committing to the final material.

Moreover, be aware that material conditions can vary, even if they are of the same type. Testing on actual samples of the material you will use in your main project will help you adjust settings more precisely.

X. Safety in Working with Laser Cutters

Safety should always be the top priority when working with laser cutters. Use protective eyewear specifically designed to block laser radiation and protect your eyes. Research and follow all safety guidelines provided by your machine’s manufacturer.

Ensure that the workspace is clean and free of obstructions to prevent accidents. Place warning signs and ensure that anyone nearby understands the risks and safety precautions.

XI. Exploring Creativity with Laser Cutters

With fundamental skills mastered, it’s time to explore new creative frontiers with your laser cutter. Experiment with unusual materials and unique combinations to discover new textures and visual effects. Laser cutters are also ideal for creating intricate details and complex patterns that can elevate your projects to new creative heights.

Stay informed about the latest trends and technological advances in the world of laser cutters. Software and hardware updates may offer new features and capabilities that further expand your machine’s possibilities.

Conclusion: Mastering the Art of Laser Cutters

Mastering the art of laser cutters is a continuous journey of learning and application. Adopting best practices not only enhances the quality of projects but also ensures efficient and safe work. By following this comprehensive guide, you will equip yourself with the knowledge and skills needed to make the most of laser cutters and take your creations to new creative heights. Consistent practice and experimentation will turn you into an expert in using these powerful tools that have transformed how we approach cutting and engraving in the modern era.