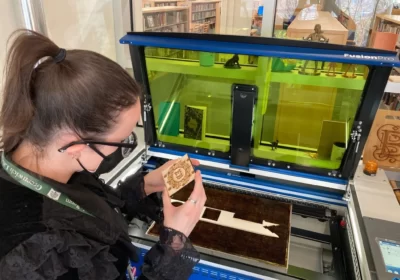

Epilog Fusion Pro

Laser Cut Master

Empower your creativity with the unmatched precision of the Epilog Fusion Pro laser cutter: where innovation meets perfection in every engraving and cut.

**In our reviews we review products that we think are useful to our readers. If you purchase through links on this page, we may earn a small commission.

The Best of the Epilog Fusion Pro laser cutter.

Epilog Fusion Pro: Elevate your projects with precision cuts, intricate engravings, and limitless creative possibilities.

- 🟢 Advanced Precision.

- 🟢 Superior Versatility.

- 🟢 Efficient Speed.

- 🟢 Intuitive Interface.

- 🟢 Durability and Reliability.

Discover unparalleled precision and versatility with the Epilog Fusion Pro laser cutter. Elevate your projects with intricate details and flawless cuts. Experience efficient workflows through its user-friendly interface, combining speed with durability. Unleash your creativity with a tool that seamlessly adapts to diverse materials, setting new standards in laser cutting excellence.

Advantages and Disadvantages of the Epilog Fusion Pro Laser Cutter

Pros

🟢 Unmatched Precision: Ensures precise cuts and engravings for detailed projects.

🟢 Advanced Versatility: Adaptable to a wide range of materials, from wood to acrylic and metal.

🟢 Swift Efficiency: Its cutting speed optimizes production times, enhancing work efficiency.

🟢 Intuitive Interface: User-friendly, with an interface that simplifies setup and operation.

🟢 Durability and Reliability: Robust construction for consistent and lasting performance.

Contras

🔴 High Cost: Its advanced technology can be expensive compared to basic models.

🔴 Considerable Size and Weight: May require significant space and be heavy, limiting mobility.

🔴 Requires Specialized Maintenance: High-tech components may need specialized maintenance, increasing long-term costs.

🔴 Energy Consumption: May have considerable energy consumption, affecting operational costs.

🔴 Learning Curve: For users unfamiliar with laser technology, there might be an initial learning curve.

Features of the Epilog Fusion Pro laser cutter

State-of-the-Art Precision

The Epilog Fusion Pro incorporates cutting-edge laser technology, ensuring precise cuts and engravings. Its automatic focus system and the ability to adjust laser power allow for intricate details and impeccable results in various projects.

Material Versatility

Engineered to surpass limits, this laser cutter handles diverse materials with ease. From wood and acrylic to metals, the Fusion Pro offers the versatility needed for successful creative projects and industrial applications.

Optimized Speed

Efficiency is key, and the Fusion Pro understands this. Its fast cutting speed not only improves production times but also allows for agile project execution, maximizing productivity in every work session.

Intuitive Touchscreen Interface

User-friendliness is essential. With an intuitive touchscreen control panel, the Fusion Pro simplifies setup and operation. From file loading to customization of settings, this user-friendly interface makes the experience seamless, even for those new to laser cutters.

Click to choose the model you like the most, or the one with the most discount.

Epilog Fusion Pro 24.

Epilog Fusion Pro 36.

Epilog Fusion Pro 48.

Guide to Efficient and Safe Use of the Epilog Fusion Pro Laser Cutter

- Understand Specifications: Before starting, familiarize yourself with the specifications of the Epilog Fusion Pro. Understand its cutting capacity, maximum material dimensions, and any thickness restrictions. This will allow you to plan your projects effectively.

- Installation and Setup: Ensure that the Fusion Pro is installed in a suitable environment with enough space and a stable power source. Follow the user manual for the initial setup and connect the machine to your design system using the recommended software.

- Safety First: Before turning on the machine, check that all components are in place and in good condition. Use personal protective equipment, such as safety glasses, to prevent injuries. Familiarize yourself with emergency stop procedures.

- Material Preparation: Ensure the material you are using is compatible with the Fusion Pro and is properly placed on the work surface. Adjust the height and position of the laser head according to the manufacturer’s recommendations.

- Design File Configuration: Prepare your design using compatible computer-aided design (CAD) software. Adjust settings according to the type of cut or engraving you intend to perform. Consider laser power, cutting speed, and frequency.

- Test on Sample Material: Before running your final design, perform tests on a piece of material similar to what you plan to use. This allows you to adjust settings as needed and ensures you will achieve the desired results.

- Start of Operation: Initiate the cutting or engraving process following the software instructions. Monitor progress and ensure the machine is functioning correctly. Maintain constant vigilance during operation.

- Smoke and Residue Extraction: If the Fusion Pro is equipped with a smoke extraction system, ensure it is functioning correctly to maintain a clean and safe working environment. Remove generated residues after each operation.

- Regular Maintenance: Schedule regular maintenance as per the manufacturer’s instructions. This may include cleaning lenses, checking connections, and replacing worn-out parts. Proper maintenance will extend the machine’s lifespan.

- Ongoing Training: Stay updated on new features and software updates for the Fusion Pro. Participate in training sessions and workshops to improve your skills and fully understand the capabilities of the machine.

- Record Keeping: Keep detailed records of each project, including cutting settings, materials used, and results obtained. This will facilitate the repetition of successful projects and troubleshooting if needed.

- Collaboration and Community: Join online communities or user groups for the Fusion Pro to share experiences, get tips, and learn new techniques. Collaboration can be invaluable for expanding your skills and knowledge.

By following this guide, you can make the most of the Epilog Fusion Pro laser cutter, ensuring precise and safe results in your projects.

Video review of the Epilog Fusion Pro laser cutter

Discover the laser cutting revolution with the Epilog Fusion Pro. Wondering how this incredible machine can transform your projects? We’ll delve into the unparalleled fascinating precision, advanced versatility, and other features that make the Fusion Pro the ideal choice. From intricate engravings to swift and efficient cuts, this laser cutter redefines creative boundaries. Immerse yourself in innovation and unlock the full potential of your creativity. Click to find out why the Epilog Fusion Pro is the ultimate tool to take your ideas to the next level! 🚀🔍 #EpilogFusionPro #LaserCutting #CreativeInnovation #LaserCutMaster

Definite Advantages for Choosing the Epilog Fusion Pro Laser Cutter!

- 🟢 Advanced Precision.

- 🟢 Superior Versatility.

- 🟢 Efficient Speed.

- 🟢 Intuitive Interface.

- 🟢 Durability and Reliability.