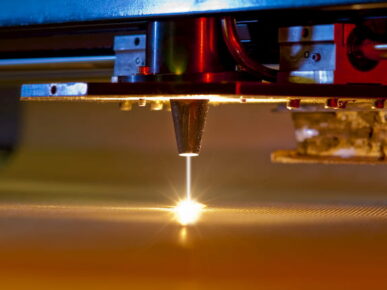

Become an Expert: Advanced Strategies for Laser Cutters

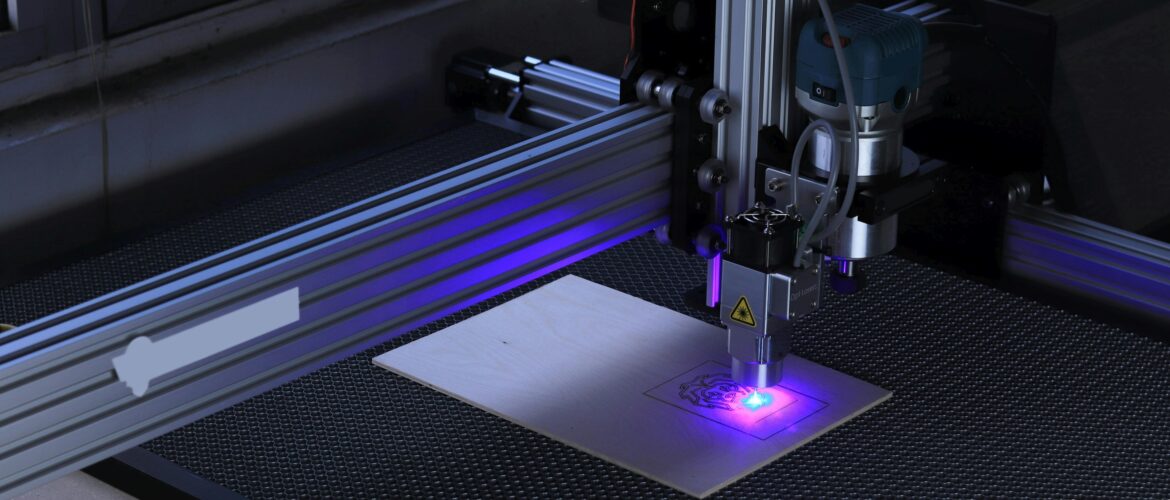

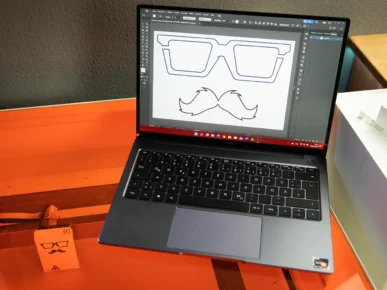

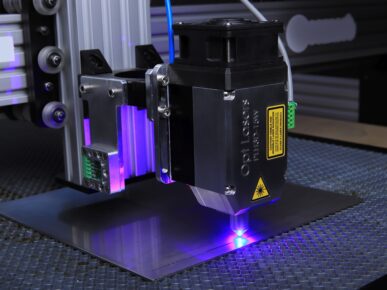

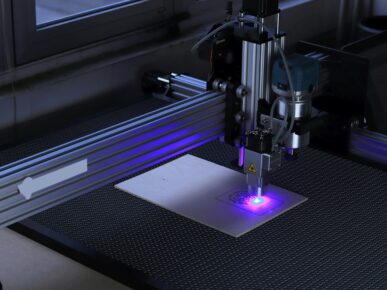

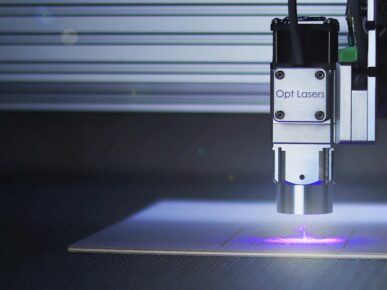

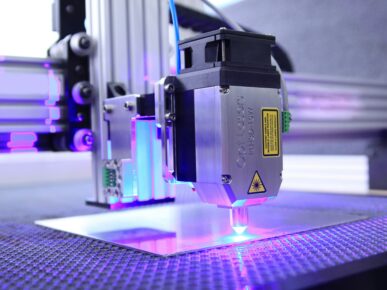

Laser cutters, with their ability to achieve precise cuts and intricate engravings, have revolutionized the fields of manufacturing and design. Those aspiring to become experts in laser cutter usage must delve beyond the basics and explore advanced strategies to make the most of these powerful tools. In this extended article, we will break down advanced strategies that will aid you in reaching the expert status in the fascinating world of laser cutters.