Maintain Precision: The Importance of Regularly Cleaning the Lens of Your Laser Cutter

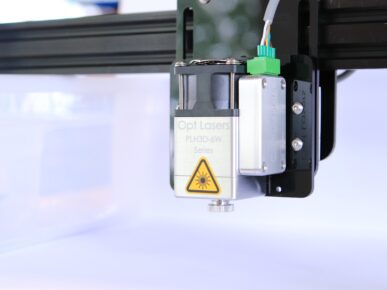

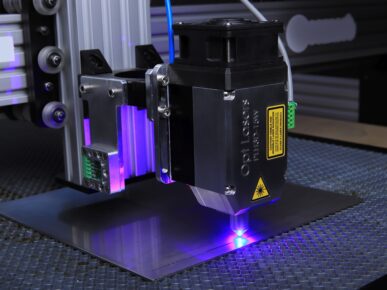

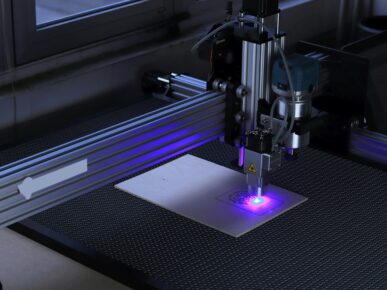

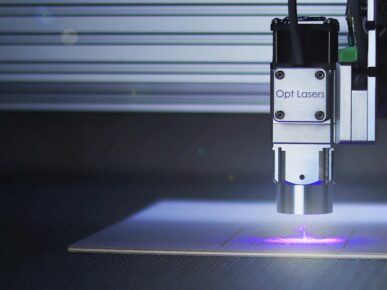

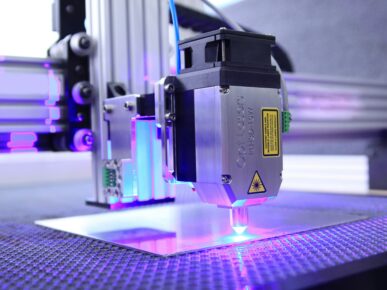

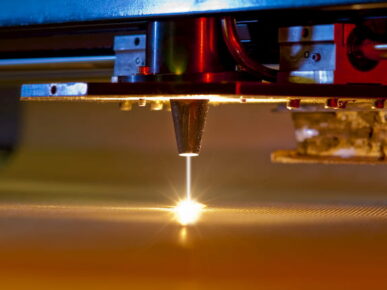

Laser technology has radically transformed the way we manufacture and cut a wide range of materials, from metals to acrylics and wood. The precision and cleanliness of cuts made by a laser cutter depend on various factors, and one of the most crucial is the condition of the focusing lens. Regularly cleaning this component is essential to ensure clean and precise cuts in all your projects. In this article, we will explore why it is crucial to keep the lens of the laser cutter clean, how to do it properly, and the benefits that come from this practice.

Why is it important to clean the lens of the laser cutter?

The focusing lens of a laser cutter is a vital component that plays a crucial role in the quality of the cuts made. Its main function is to focus the laser beam at a specific point on the material being cut, ensuring millimeter precision in each cut. However, when the lens is dirty or contaminated, this precision is compromised. Dirt, dust, and residues can quickly accumulate on the surface of the lens during the cutting process. This is especially true when working with materials like wood or acrylic, which tend to release tiny particles during cutting. Additionally, smoke and gases generated during the cutting process can deposit on the lens, reducing its clarity and efficiency.

How to clean the lens properly?

Cleaning the lens of a laser cutter is not a trivial task and requires caution and attention to detail to avoid damaging the delicate surface. Below, we will detail the necessary steps to carry out this task safely and effectively:

- Turn off the cutting machine: Before starting the cleaning process, it is imperative to completely turn off the laser cutter and disconnect it from the power source to prevent accidents and injuries.

- Remove the focusing lens: Carefully and following the instructions provided by the manufacturer, remove the focusing lens from the laser cutter. It is essential to handle the lens with care to avoid scratching or damaging the surface during the removal process.

- Inspect the lens: Before proceeding with the cleaning, thoroughly examine the lens for any signs of damage or severe contamination. If the lens is very dirty or shows significant damage, it is advisable to consider replacing it instead of attempting to clean it.

- Gently clean the lens: Use a soft and clean cloth to gently clean the surface of the lens. Isopropyl alcohol or a specific cleaner for laser lenses is recommended to effectively remove dirt and residues. It is crucial to avoid applying too much pressure during this process to prevent potential damage to the lens.

- Carefully dry the lens: Once you have cleaned the lens, make sure to dry it completely before reinstalling it in the laser cutter. Use a clean and dry cloth to remove any liquid residue and ensure that the lens is completely dry before reinstallation.

- Reinstall the lens correctly: With caution, reinstall the lens in its original position following the instructions provided by the manufacturer. Make sure that the lens is properly aligned and secured in place to ensure optimal performance.

- Perform verification cutting tests: After cleaning and reinstalling the lens, it is advisable to perform some cutting tests on scrap material to verify that the laser cutter is functioning correctly and that the cuts are precise and clean.

Benefits of regularly cleaning the lens of the laser cutter

Keeping the lens of the laser cutter clean offers several significant benefits in terms of cut quality and equipment lifespan. Some of these key benefits include:

- More precise and consistent cuts: A clean lens ensures that the laser beam is properly focused at the desired point, resulting in more precise cuts and cleaner edges in your projects.

- Increased efficiency and productivity: By removing dirt and residues from the lens, the likelihood of laser beam deviation or weakening is reduced, which can increase the efficiency of the cutting process and reduce production time.

- Reduced risk of equipment damage and extended lifespan: The accumulation of dirt on the lens not only affects cut quality but can also permanently damage the equipment if not properly addressed. Regularly cleaning the lens helps prevent such costly damages and prolongs the overall lifespan of the equipment.

- Long-term time and cost savings: Keeping the lens clean and in good condition can reduce the need for frequent replacement, thus saving time and money in the long run by avoiding costly repairs and maintenance.

Conclusion

Regular cleaning of the lens of the laser cutter is an essential practice to ensure clean, precise, and consistent cuts in all your projects. By following the appropriate steps and taking precautions, you can keep the lens in optimal condition and extend the lifespan of your equipment. Remember that lens cleaning not only improves the quality of your cuts but also protects your investment and ensures optimal performance of your laser cutter over time.

You may also like