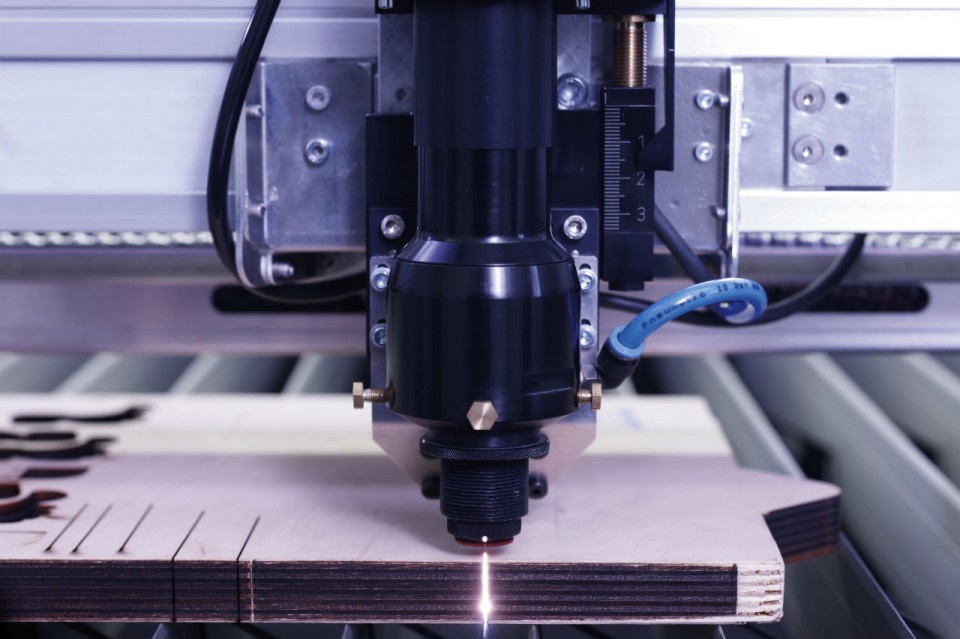

The best Nd Laser Cutter.

Best Nd Laser Cutter.

According to our analysis, the best Nd Laser Cutter is the Trotec Speedy Series

How have we made this comparison of laser cutters?

In our laser cutter comparison, we follow a meticulous process:

- Initial Research: We identify popular models through reviews and expert.

- opinions. Diverse Selection: We choose models representing various features, such as price, type, and key functions.

- Evaluation Criteria: We define criteria such as cutting quality, convenience, and durability for each model.

- Practical Testing: We conduct hands-on tests, including cutting sessions and evaluation of special features.

- Comparative Analysis: We compile results into a detailed comparison based on objective data and practical experience.

- User and Expert Opinions: We incorporate real user feedback and expert evaluations to provide a comprehensive perspective.

- Periodic Updates: Committed to regularly updating the comparison to reflect changes in the market.

Our goal is to provide you with accurate and up-to-date information, helping you make informed decisions when choosing your ideal laser cutter.

The Best Laser Cutter Nd Value for Money: Bystronic BySprint Fiber

PROS

CONS

🔴 Initial Cost: The initial acquisition cost can be relatively high, especially for models with advanced features and enhanced cutting capabilities.

🔴 Power Consumption: Some models of Trotec Speedy Series Nd laser cutters may have considerable power consumption, impacting long-term operating costs.

🔴 Limited Workspace Size: Depending on the specific model, the workspace size of Trotec Speedy Series laser cutters can be limited, which may be a consideration for larger projects.

🔴 Maintenance Requirements: Like any high-precision equipment, these laser cutters may require regular maintenance to ensure optimal performance, potentially incurring additional costs.

🔴 Space Needed for Accessories: Optional accessories, such as advanced extraction systems or cooling systems, may require additional space in the workspace.

Read our full review of the Bystronic BySprint Fiber.

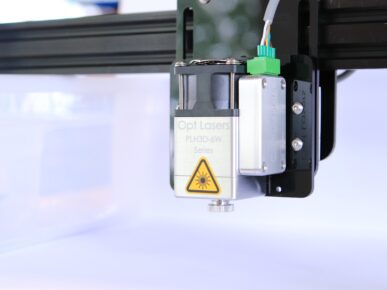

Choosing the Best Nd Laser Cutter: A Comprehensive Guide to Decision-Making

Nd laser cutters, incorporating neodymium technology, stand as cutting-edge tools revolutionizing the landscape of cutting and engraving. As the market burgeons with an array of options, the pivotal task of selecting the optimal Nd laser cutter necessitates a deep dive into considerations that extend beyond the surface. In this expansive guide, we will meticulously dissect each facet, shedding light on the advantages, disadvantages, and pivotal factors influencing the choice of the best Nd laser cutter.

1. Initial Considerations:

Embarking on the journey of acquiring the best Nd laser cutter demands a meticulous assessment of your unique needs. Beyond material type and precision requirements, consider factors such as the expected frequency of use, compatibility with existing workflows, and the scalability of the machine in alignment with your business growth.

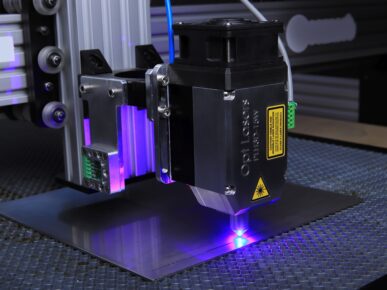

2. Precision and Cutting Quality:

Delve into the specific precision requirements dictated by your intended applications. Consider not only the advertised precision but also real-world performance. Explore user testimonials and case studies to understand how well the laser cutter maintains precision over extended periods and varying workloads.

3. Speed and Operational Efficiency:

While cutting speed is a crucial consideration, assess how well the laser cutter maintains efficiency under real operating conditions. Investigate features such as dynamic autofocus and adaptive speed control, which can optimize processing speed while ensuring consistent quality across different materials.

4. Material Versatility:

Beyond basic material compatibility, scrutinize the machine’s adaptability to a broad spectrum of materials. Investigate whether the laser cutter can seamlessly transition between metals, plastics, and organic materials without sacrificing efficiency or requiring frequent adjustments.

5. Power Consumption and Efficiency:

Evaluate the laser cutter’s power consumption in relation to its performance. Seek models with energy-efficient components, including power sources and cooling systems. Energy efficiency not only contributes to lower operating costs but also aligns with sustainable practices.

6. Workspace Size and Configuration:

Consider not only the physical dimensions of the laser cutter but also the overall workspace requirements. Explore features like pass-through doors and modular designs that facilitate the handling of larger materials or continuous workflows, ensuring flexibility and adaptability in various production scenarios.

7. Software and Usability:

Examine the software ecosystem surrounding the Nd laser cutter. Beyond user-friendliness, delve into the capability for software updates, compatibility with popular design programs, and the availability of community support. A robust software infrastructure enhances the overall usability and longevity of the laser cutter.

8. Maintenance and Post-Sale Support:

Scrutinize the ease of maintenance and the availability of post-sale support. Investigate whether the manufacturer provides comprehensive documentation, training resources, and responsive customer support. A well-supported machine translates to minimal downtime and efficient issue resolution.

9. Long-Term Operating Costs:

Look beyond the initial acquisition cost and delve into the ongoing operational expenses. Assess the costs of consumables, such as laser tubes and lenses, and explore whether the machine’s design facilitates easy maintenance, potentially reducing the frequency and complexity of required service.

10. Future Upgrades and Expansions:

Anticipate the future growth of your business and the evolving demands of your production needs. Choose an Nd laser cutter that not only meets your current requirements but also has provisions for upgrades and expansions. Modular designs and compatibility with future technologies can extend the machine’s relevance.

11. Comparison with Competing Models:

Conduct an in-depth comparison with competing Nd laser cutter models. Look beyond technical specifications and user reviews to explore the availability of aftermarket accessories, third-party enhancements, and the overall ecosystem surrounding each model. A holistic comparison will reveal nuances that may impact long-term satisfaction.

12. Market Trends and Emerging Technologies:

Stay abreast of current market trends and emerging technologies in the realm of Nd laser cutters. Investigate whether manufacturers offer firmware updates and if the machine can adapt to emerging industry standards. A forward-looking approach ensures that your investment remains relevant amid technological advancements.

Conclusion:

In conclusion, the quest for the best Nd laser cutter is a multifaceted journey that demands careful consideration of numerous factors. From precision and efficiency to long-term costs and adaptability, each aspect plays a pivotal role in determining the suitability of the machine for your unique requirements. Take the time to explore, question, and align your choice with both current and future needs. In doing so, you’re not merely investing in a machine; you’re charting a course for sustained success and innovation in your industry.

Latest news in Laser Cutters.

Complete catalog of Laser Cutters.

Preguntas Frecuentes

Los diferentes modelos de audífonos inalámbricos de Apple incluyen los AirPods, los AirPods Pro y los AirPods Max. Cada modelo tiene sus propias características y capacidades únicas.

Los AirPods son los auriculares inalámbricos estándar de Apple. Los AirPods Pro ofrecen características adicionales como cancelación activa de ruido y un ajuste más seguro. Los AirPods Max son auriculares over-ear de alta calidad con cancelación activa de ruido y una experiencia auditiva premium.

Para emparejar tus AirPods con un dispositivo iOS, simplemente abre la caja de los AirPods cerca del dispositivo y sigue las instrucciones en la pantalla. Para emparejarlos con una Mac, ve a Preferencias del Sistema > Bluetooth y selecciona tus AirPods en la lista de dispositivos disponibles.

La duración de la batería de los AirPods puede variar según el modelo y el uso, pero por lo general, ofrecen varias horas de reproducción de audio con una sola carga. Los estuches de carga también pueden proporcionar múltiples cargas adicionales.

Los AirPods de primera y segunda generación no están clasificados como resistentes al agua ni al sudor, por lo que se deben tener precauciones al usarlos durante actividades que impliquen sudor o exposición al agua. Los AirPods Pro, en cambio, tienen una clasificación IPX4, lo que significa que son resistentes al agua y al sudor en cierta medida. Sin embargo, no se recomienda sumergirlos en agua.