The best Solid-State Laser Cutter.

Best Solid-State Laser Cutter.

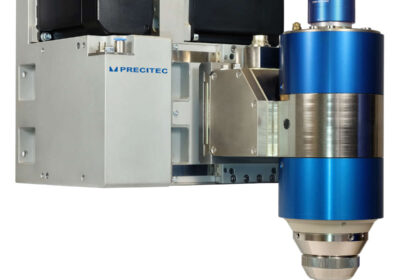

According to our analysis, the best Solid-State Laser Cutter is the Trotec SolidCutter PRECITEC

How have we made this comparison of laser cutters?

In our laser cutter comparison, we follow a meticulous process:

- Initial Research: We identify popular models through reviews and expert.

- opinions. Diverse Selection: We choose models representing various features, such as price, type, and key functions.

- Evaluation Criteria: We define criteria such as cutting quality, convenience, and durability for each model.

- Practical Testing: We conduct hands-on tests, including cutting sessions and evaluation of special features.

- Comparative Analysis: We compile results into a detailed comparison based on objective data and practical experience.

- User and Expert Opinions: We incorporate real user feedback and expert evaluations to provide a comprehensive perspective.

- Periodic Updates: Committed to regularly updating the comparison to reflect changes in the market.

Our goal is to provide you with accurate and up-to-date information, helping you make informed decisions when choosing your ideal laser cutter.

The Best Solid-State Laser Cutters Value for Money: SolidCutter PRECITEC

PROS

CONS

🔴 Photoelectric conversion rate: The photoelectric conversion rate of CO2 lasers is only about 10%.

🔴 Discharge stability: For CO2 gas lasers, the stability of high-power laser discharge must be addressed.

🔴 Core technologies: Since most of the core and key technologies of CO2 lasers are in the hands of manufacturers.

Read our full review of the SolidCutter PRECITEC.

Choosing the Best Solid-State Laser Cutter: A Comprehensive Analysis

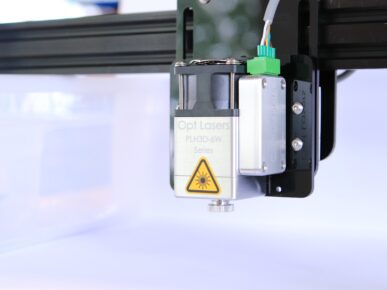

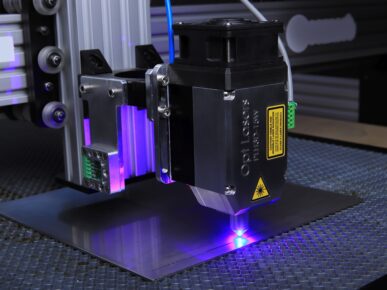

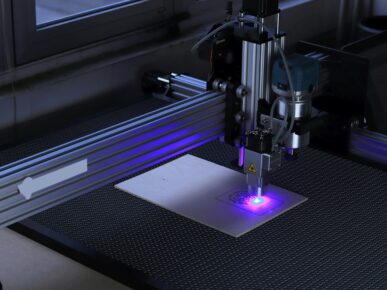

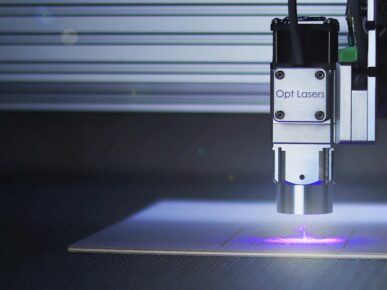

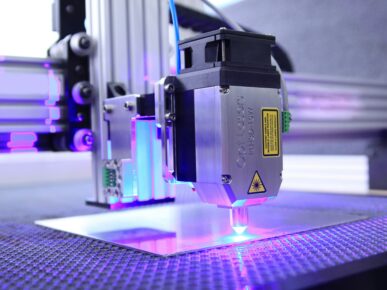

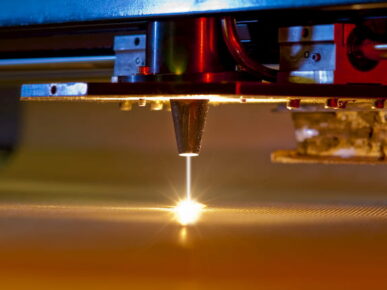

Laser technology has revolutionized the precision cutting and engraving landscape, and among the myriad options available, solid-state laser cutters have emerged as a leading choice. These machines utilize solid-state active mediums like crystals or ceramics to generate powerful and precise laser beams. When contemplating the acquisition of a solid-state laser cutter, conducting an in-depth analysis becomes paramount to selecting the optimal option aligned with your unique requirements. Let’s delve deeper into key considerations for choosing the best solid-state laser cutter.

1. Precision and Cutting Quality:

Precision stands as a cornerstone in any cutting or engraving application. Solid-state laser cutters excel in delivering high precision, enabling the handling of intricate cutting profiles and achieving remarkable levels of detail. Assess the machine’s capability to uphold this precision across a diverse array of materials and varying working conditions.

2. Material Versatility:

A distinct advantage of solid-state laser cutters lies in their material versatility. These machines showcase compatibility with a wide spectrum of materials, ranging from metals and plastics to woods and composite materials. When selecting a laser cutter, carefully consider the diversity of materials integral to your project portfolio.

3. Efficiency and Cutting Speed:

Efficiency and cutting speed stand as pivotal factors influencing productivity. Solid-state laser cutters are renowned for their rapid and efficient operation, streamlining the production process. Evaluate cutting rates meticulously, aligning them with the specific demands of your projects and operational timelines.

4. Cost-Effectiveness and Energy Savings:

In the realm of cost-effectiveness and energy efficiency, solid-state laser cutters often outshine their counterparts like CO2 lasers. Their economic viability is further enhanced by a reduced environmental footprint, as they eschew gas emissions. When making a decision, factor in long-term operating costs and the eco-conscious impact of your choice.

5. Stability and Maintenance:

The stability of laser discharge and maintenance requirements are critical considerations. Thoroughly examine the stability of the laser discharge, especially in high-power models. Additionally, scrutinize the regular maintenance needs and ascertain the accessibility of robust technical support provided by the manufacturer.

6. Core Technologies and Future Upgrades:

Given that core technologies of solid-state laser cutters are often proprietary, the potential for future upgrades becomes a pivotal consideration. Opt for a machine that exhibits adaptability to emerging technologies and updates, ensuring a prolonged lifespan and relevance in a dynamically evolving landscape.

7. Size and Workspace Configuration:

The size and configuration of the workspace wield considerable influence, especially when tackling projects of varying dimensions. Ensure that the selected laser cutter boasts a spacious and adaptable workspace, aligning seamlessly with the scale and nature of your intended applications.

8. Manufacturer Reputation and User Reviews:

Delve into the manufacturer’s reputation, placing a premium on a solid track record within the solid-state laser cutter industry. User reviews and testimonials serve as valuable resources, providing practical insights into the real-world performance of specific models across diverse working environments.

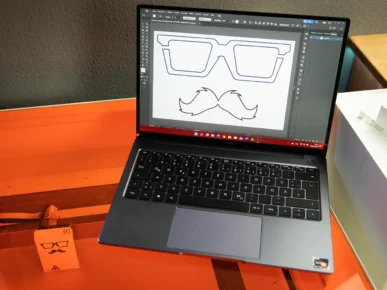

9. Software Integration and Usability:

The associated software and overall usability of the laser cutter significantly impact user experience. Seek out machines with intuitive and user-friendly software interfaces. A seamless integration capability with other programs enhances operational efficiency and workflow cohesion.

10. Warranties and After-Sales Service:

Review the warranty policies and after-sales service offerings from the manufacturer. A comprehensive warranty coupled with efficient after-sales support provides assurance and facilitates swift resolution of any potential issues, safeguarding your investment.

In conclusion, the process of selecting the best solid-state laser cutter demands a meticulous examination of your unique operational requirements. Investing time in research and comparison ensures an informed decision, aligning your choice with both immediate needs and future growth trajectories.

Latest news in Laser Cutters.

Complete catalog of Laser Cutters.

Preguntas Frecuentes

Los diferentes modelos de audífonos inalámbricos de Apple incluyen los AirPods, los AirPods Pro y los AirPods Max. Cada modelo tiene sus propias características y capacidades únicas.

Los AirPods son los auriculares inalámbricos estándar de Apple. Los AirPods Pro ofrecen características adicionales como cancelación activa de ruido y un ajuste más seguro. Los AirPods Max son auriculares over-ear de alta calidad con cancelación activa de ruido y una experiencia auditiva premium.

Para emparejar tus AirPods con un dispositivo iOS, simplemente abre la caja de los AirPods cerca del dispositivo y sigue las instrucciones en la pantalla. Para emparejarlos con una Mac, ve a Preferencias del Sistema > Bluetooth y selecciona tus AirPods en la lista de dispositivos disponibles.

La duración de la batería de los AirPods puede variar según el modelo y el uso, pero por lo general, ofrecen varias horas de reproducción de audio con una sola carga. Los estuches de carga también pueden proporcionar múltiples cargas adicionales.

Los AirPods de primera y segunda generación no están clasificados como resistentes al agua ni al sudor, por lo que se deben tener precauciones al usarlos durante actividades que impliquen sudor o exposición al agua. Los AirPods Pro, en cambio, tienen una clasificación IPX4, lo que significa que son resistentes al agua y al sudor en cierta medida. Sin embargo, no se recomienda sumergirlos en agua.