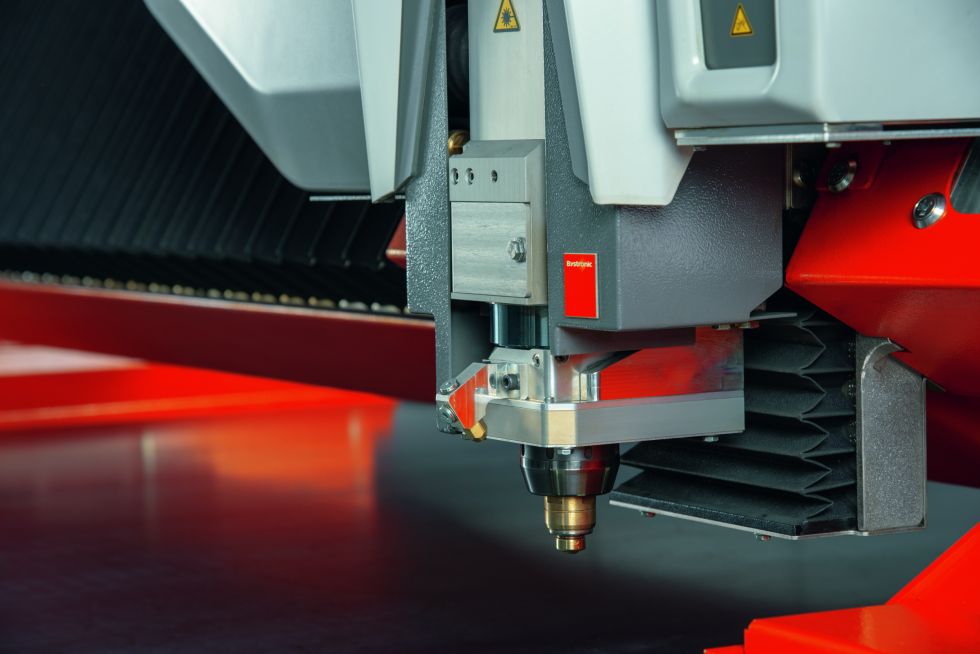

Bystronic ByStar Fiber

Laser Cut Master

Revolutionize your production with the unmatched precision of the Bystronic ByStar Fiber laser cutter: power, speed, and quality in every cut, propelling your business towards new horizons.

**In our reviews we review products that we think are useful to our readers. If you purchase through links on this page, we may earn a small commission.

The Best of the Bystronic ByStar Fiber laser cutter.

Elevate your fabrication game with Bystronic ByStar Fiber—where precision meets efficiency for unparalleled laser cutting excellence..

- 🟢 High Cutting Speed.

- 🟢 Unmatched Precision.

- 🟢 Material Versatility.

- 🟢 Energy Efficiency.

- 🟢 Advanced Automation.

Maximize precision and efficiency with the TruLaser Series laser cutter. Unleash unparalleled versatility across materials, achieve intricate designs effortlessly, and elevate production speed, all driven by state-of-the-art automation for a seamless and superior cutting experience.

Advantages and Disadvantages of the TruLaser Series Laser Cutter

Pros

🟢 Exceptional Precision: The TruLaser Series stands out for its extraordinary cutting precision, ensuring high-quality results in various applications.

🟢 Material Versatility: This laser cutter is compatible with a wide range of materials, from metals to plastics and wood, offering flexibility in diverse projects.

🟢 Production Efficiency: With superior cutting speeds, the TruLaser Series improves production efficiency, reducing delivery times and optimizing processes.

🟢 Advanced Automation: The integration of advanced automation systems simplifies operation, allowing continuous production and minimizing the need for manual intervention.

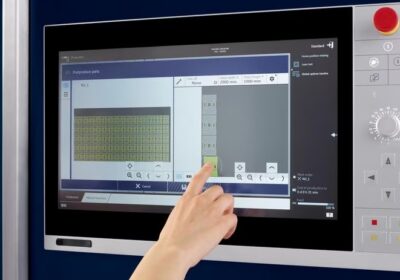

🟢 Intuitive Design and Efficient Programming: Its intuitive user interface and the ability to work with efficient programming software make it easy to create complex designs and execute custom projects.

Contras

🔴 High Initial Cost: The initial investment can be substantial, potentially limiting access to this technology for small businesses or workshops with tight budgets.

🔴 Specialized Maintenance: The need for specialized maintenance may result in additional costs over time, requiring trained personnel to ensure optimal performance.

🔴 Considerable Size and Weight: Some models of the TruLaser Series can be bulky, posing challenges in terms of space and logistics in smaller work environments.

🔴 Power Requirements: These laser cutters may require a significant power source, potentially increasing operating costs, especially in regions with high electricity rates.

🔴 Learning Curve: Mastering all the advanced features of the TruLaser Series may take time, presenting a challenge for those new to handling high-tech laser equipment.

Features of the TruLaser Series laser cutter

Efficient Programming Software

The TruLaser Series is distinguished by its compatibility with highly efficient and user-friendly programming software. This software facilitates not only the simple creation but also the agile modification of complex and customized designs, allowing exceptional adaptability to specific project needs. The intuitive interface of the software provides operators with precise control over the programming process, enhancing workflow efficiency and overall productivity

Enhanced Safety Features

Safety is a fundamental priority in the TruLaser Series, which incorporates advanced safety features. Smart sensors and emergency stop systems ensure a secure working environment. The machine proactively responds to potentially hazardous situations, minimizing risks and providing operators with the peace of mind to work safely and reliably with cutting-edge laser cutting equipment.

Capability for Custom Projects

The TruLaser Series goes beyond by offering the ability to execute custom projects and create prototypes thanks to its ability to work with intricate designs and specific requirements. From complex geometric shapes to fine details, this laser cutter allows the materialization of creative ideas and the production of unique pieces, driving innovation in manufacturing.

Handling Large Volumes

Designed for efficiency in mass production, the TruLaser Series demonstrates its ability to handle large volumes of work efficiently. Whether in mass component manufacturing or continuous production, this laser cutter provides the versatility needed to tackle the challenges of large-scale industrial production, ensuring consistent and high-quality results.

Click to choose the model you like the most, or the one with the most discount.

TruLaser 1030.

TruLaser 3030.

TruLaser 5030.

Guide to Efficient and Safe Use of the TruLaser Series Laser Cutter

Embarking on a journey to harness the full potential of the TruLaser Series involves a holistic approach encompassing technical mastery, safety diligence, and a commitment to continuous improvement. Let’s delve deeper into each facet:

1. Familiarize Yourself with the User Manual:

- Transform the user manual into a living document. Annotate key sections based on your operational insights. Establish a system for updating and disseminating relevant information to all operators.

2. Initial Setup:

- Go beyond basic setup by implementing a thorough checklist. Document each step, including specific tooling requirements, environmental conditions, and pre-check procedures to ensure consistency across setups.

3. Precise Calibration:

- Institute a calibration log, detailing calibration dates, results, and any adjustments made. Consider implementing predictive maintenance techniques, such as laser interferometry, to anticipate calibration needs before deviations impact performance.

4. Design and Programming:

- Foster expertise in the CAD software by encouraging collaboration between operators and design engineers. Establish a feedback loop for continuous improvement, incorporating lessons learned into future design and programming practices.

5. Initial Testing:

- Elevate your testing protocols by implementing statistical analysis. Develop a standardized testing matrix covering various material types, thicknesses, and cut complexities. Leverage statistical process control to identify trends and potential process improvements.

6. Safety at the Forefront:

- Cultivate a safety culture through regular safety drills and simulations. Establish a safety committee to assess and address potential hazards systematically. Encourage operators to actively participate in the identification and resolution of safety concerns.

7. Material Handling:

- Optimize material logistics by integrating lean principles. Implement visual management systems to streamline material flow. Continuously solicit feedback from operators to refine material handling processes and minimize non-value-added activities.

8. Regular Maintenance:

- Elevate maintenance procedures by incorporating predictive and prescriptive maintenance strategies. Implement sensors and monitoring devices to collect real-time data on equipment health, enabling proactive interventions before issues arise.

9. Continuous Monitoring:

- Implement a real-time dashboard that visualizes key performance indicators. Empower operators with tools for in-depth analysis and decision-making. Foster a culture of continuous improvement by celebrating successes and actively addressing identified challenges.

10. Updates and Improvements: – Institutionalize a feedback loop with the manufacturer. Establish a liaison role responsible for staying abreast of new developments. Create a structured process for evaluating and implementing updates, ensuring a seamless transition to enhanced features.

11. Staff Training: – Develop a comprehensive training program with tiered levels of expertise. Encourage cross-functional training to enhance versatility among operators. Consider creating mentorship programs to facilitate knowledge transfer and skill development.

By implementing these comprehensive strategies, you create an environment where the TruLaser Series laser cutter becomes not just a tool but a dynamic and evolving asset within your manufacturing ecosystem. Regularly reassess and refine your strategies to stay ahead of technological advancements and industry best practices.

Video review of the TruLaser Series laser cutter

Discover the excellence of the TruLaser Series laser cutter in action. In our latest review video, we delve deep into the advanced features and exceptional performance that this machine brings to the world of laser cutting. From its millimeter precision to its ability to handle a variety of materials, you’ll immerse yourself in a detailed analysis that highlights its unique benefits. Don’t miss the chance to witness up close how the TruLaser Series redefines industry standards. Click to watch the video now and find out why this laser cutter is the preferred choice for demanding and customized projects!

Definite Advantages for Choosing the TruLaser Series Laser Cutter!

- 🟢 Precision and Cutting Quality.

- 🟢 Material Versatility.

- 🟢 Efficiency in Production Time.

- 🟢 Programming and Automation.

- 🟢 Design Flexibility.