How to Choose the Perfect Laser Cutter for Your Needs

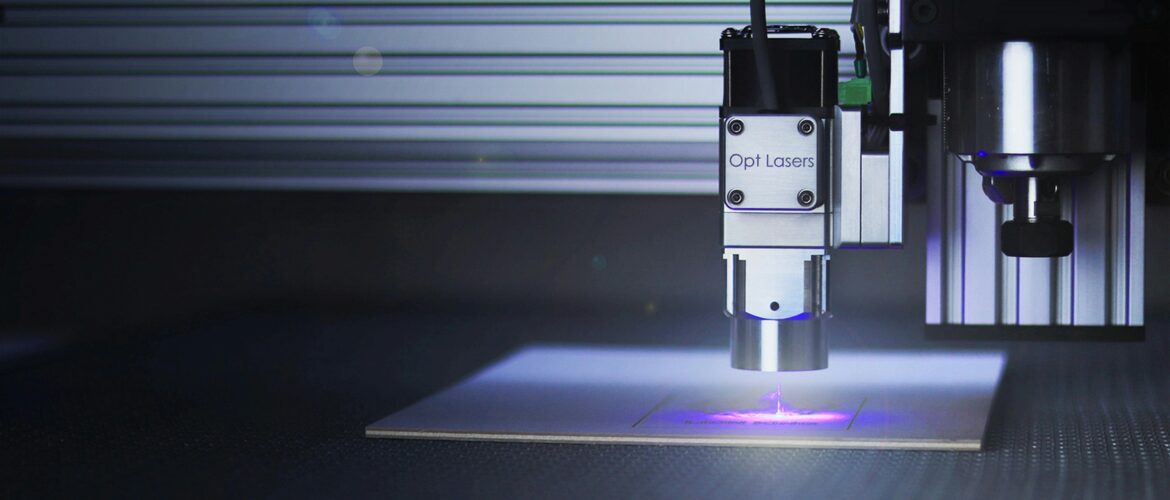

Laser cutters, with their ability to make precise cuts across a variety of Elements, have become Important tools in the realms of creation and design. However, selecting the right laser cutter for your specific needs can be a challenging process. In this regard, we’ll delve more deeply into the key aspects to consider when choosing the perfect laser cutter for your projects.

TIPS

Define Your Goals and Projects

Before diving into the selection of a laser cutter, it’s crucial to have a clear vision of your goals and the types of projects you plan to undertake. If your focus is primarily artistic, you may need a machine that offers high resolution and precision. On the other hand, if you’re thinking about large-scale production, cutting speed and efficiency will be critical factors.

Moreover, consider versatility as well. Are you planning to work mainly with wood, acrylic, metal, or other materials? Having a clear understanding of your goals will allow you to make more informed decisions during the selection process.

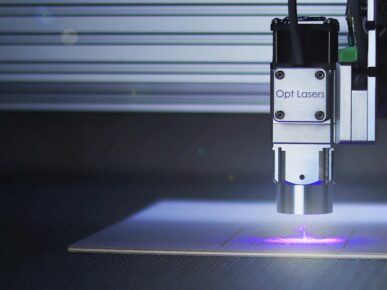

Type of Material You Plan to Cut

The range of materials a laser cutter can handle is extensive, but not all machines are equal. Some are specialized in certain types of materials, while others are more versatile. Furthermore, if your projects involve a variety of materials, ensure that the laser cutter you’re considering is compatible with all of them.

From soft woods to resilient metals, each material has its own demands, and the machine should be able to adapt. Check the manufacturer’s specifications to ensure that the laser cutter can handle the diversity of materials you plan to use.

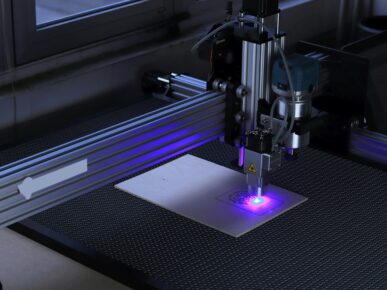

Workspace Size and Cutting Dimensions

Workspace size and cutting dimensions are critical aspects in determining a machine’s versatility. Larger projects require a laser cutter with a substantial workspace. Additionally, check the maximum and minimum cutting dimensions the machine offers, as this can limit or expand your creative possibilities.

Imagine having to divide a large project into several smaller pieces due to size limitations. Choosing a laser cutter with an adequate workspace for your projects will allow you to work more efficiently and without unnecessary constraints.

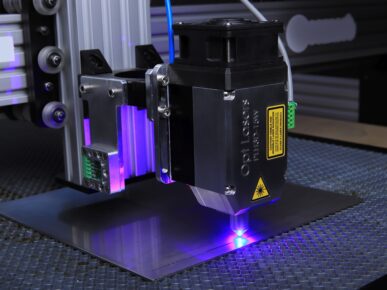

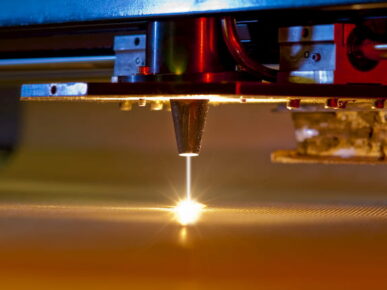

Laser Power and Cutting Speed

Laser power is a critical factor that directly influences a machine’s cutting capability. Thicker projects or denser materials will require higher power. It’s crucial to find the right balance between power and cutting speed to ensure optimal performance across a variety of projects.

If your projects involve intricate cuts on thinner materials, a machine with lower power but higher cutting speed might be more suitable. On the other hand, robust projects may require higher power for clean and efficient cuts.

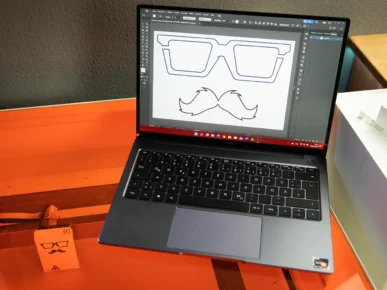

Software and User-Friendliness

The software associated with the laser cutter plays a crucial role in the user experience. Intuitive and user-friendly software can make a significant difference in project efficiency and quality. Ensure that the software allows easy import and editing of designs and check its compatibility with different file formats.

Moreover, some machines offer additional features, such as the ability to simulate cuts before executing them or the option to create designs directly in the software. These features can significantly enhance the laser cutter’s versatility and convenience.

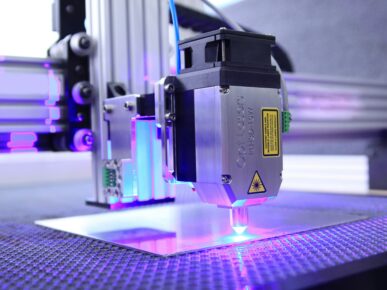

Safety Features

Laser cutters are powerful tools that require careful handling. Safety features are essential to protect the operator and prevent accidents. Ensure that the machine has effective emergency stop systems, protection against overheating, and other relevant safety features.

Additionally, some laser cutters are equipped with vision systems that detect foreign objects in the workspace, providing an additional layer of safety. Operator safety should be a priority when selecting a laser cutter.

Cost and Value for Money

Budget is undoubtedly a determining factor when selecting a laser cutter, but it’s equally crucial to consider the value for money instead of solely focusing on the initial price. A more expensive machine may offer additional features, durability, and better long-term performance, justifying the investment.

Before making a decision based solely on the price, evaluate the build quality, manufacturer reputation, and specific features that the laser cutter offers. Consider the cost as a long-term investment rather than a one-time expense.

Manufacturer’s Reputation and User Reviews

The manufacturer’s reputation and user reviews provide valuable insights into the quality and reliability of the laser cutter you’re considering. Research the manufacturer’s track record in the industry and look for feedback from users with similar needs.

Reviews can offer information on the machine’s long-term performance, build quality, customer support, and other critical aspects that may not be evident initially. Combining the manufacturer’s reputation with the experiences of previous users will give you a more comprehensive view of what to expect from the laser cutter.

In conclusion, when embarking on the journey to choose the perfect laser cutter, these considerations will guide you toward a selection that aligns with your goals and project requirements. Choose the perfect laser that meets your needs and unlocks new possibilities in your creative and manufacturing endeavors.

For additional resources on laser cutting and related topics, consider exploring our articles on advanced laser cutting techniques, innovations in laser cutting technology, and how to maintain your laser cutter for optimal performance. These resources can provide valuable insights to enhance your understanding of laser cutting processes and help you make informed decisions for your projects.

Conclusion

Choosing the perfect laser cutter for your needs involves a detailed process of assessment and consideration. Defining your goals, understanding the materials you’ll work with, and grasping the technical features of each machine are fundamental steps. The time invested in research will enable you to select a laser cutter that fits perfectly into your projects, providing precise and satisfying results in the long run. Remember that choosing the right laser cutter is an investment in your creativity and efficiency, and it’s worth dedicating the necessary time to make the right decision.