The best Tube Laser Cutter.

Best Tube Laser Cutter.

According to our analysis, the best laser tube cutting machine is the Amada LC-C12

How have we made this comparison of laser cutters?

In our laser cutter comparison, we follow a meticulous process:

- Initial Research: We identify popular models through reviews and expert.

- opinions. Diverse Selection: We choose models representing various features, such as price, type, and key functions.

- Evaluation Criteria: We define criteria such as cutting quality, convenience, and durability for each model.

- Practical Testing: We conduct hands-on tests, including cutting sessions and evaluation of special features.

- Comparative Analysis: We compile results into a detailed comparison based on objective data and practical experience.

- User and Expert Opinions: We incorporate real user feedback and expert evaluations to provide a comprehensive perspective.

- Periodic Updates: Committed to regularly updating the comparison to reflect changes in the market.

Our goal is to provide you with accurate and up-to-date information, helping you make informed decisions when choosing your ideal laser cutter.

The Best laser tube cutting machine Value for Money: Amada LC-C12

PROS

CONS

🔴 High initial cost: The LC-C12 is an expensive machine, which can be a hurdle for some companies.

🔴 Regular Maintenance: The LC-C12 requires regular maintenance to ensure optimal performance.

🔴 Cost of Replacement Parts: Replacement parts for the LC-C12 can be expensive.

🔴 Training Required: Training is required to operate the LC-C12 safely and efficiently.

🔴 High power consumption: The LC-C12 consumes a lot of power, which can be a problem in some areas.

Read our full review of the Amada LC-C12.

Complete Guide to Choosing the Best Tube Laser Cutting Machine

Tube laser cutting machines have revolutionized the metalworking industry, offering a more precise, efficient, and versatile alternative to traditional cutting methods. With a wide range of applications in sectors such as automotive, construction, furniture manufacturing, and aerospace, choosing the right machine can make a difference in the productivity and competitiveness of your business.

In this expanded guide, we will guide you step-by-step through the key aspects to consider when selecting the best tube laser cutting machine for your needs:

1. Types of Tube Laser Cutting Machines:

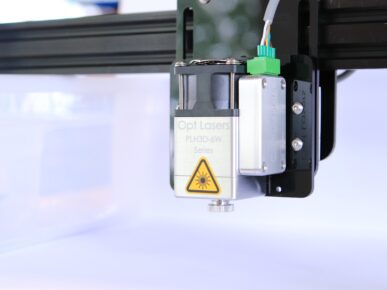

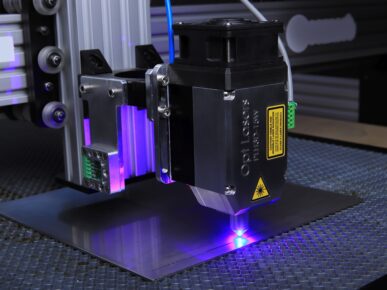

1.1. Fiber Laser Cutting Machines:

- Advantages:

- High power and cutting speed.

- Ideal for thick materials such as carbon steel and stainless steel.

- Low energy consumption and maintenance.

- Long laser life.

- Disadvantages:

- Higher initial investment compared to CO2 machines.

- Not as suitable for thin materials like aluminum.

1.2. CO2 Laser Cutting Machines:

- Advantages:

- More economical than fiber lasers.

- Suitable for thin materials such as aluminum and acrylic.

- Good cutting quality.

- Disadvantages:

- Lower power and cutting speed than fiber machines.

- Higher energy consumption and maintenance.

- Shorter laser life.

1.3. Hybrid Laser Cutting Machines:

- Advantages:

- Combine the advantages of fiber and CO2 machines.

- They can cut a wide range of materials with high precision and efficiency.

- Flexibility to adapt to different needs.

- Disadvantages:

- Higher initial investment than fiber or CO2 machines.

Application Examples:

- Fiber Laser Cutting Machines:

- Cutting steel tubes for the construction of metal structures.

- Cutting stainless steel tubes for the food industry.

- Cutting aluminum tubes for the automotive industry.

- CO2 Laser Cutting Machines:

- Cutting aluminum tubes for furniture manufacturing.

- Cutting acrylic tubes for the advertising industry.

- Cutting plastic tubes for the medical industry.

- Hybrid Laser Cutting Machines:

- Cutting carbon steel and stainless steel tubes for the petrochemical industry.

- Cutting aluminum and titanium tubes for the aerospace industry.

- Cutting tubes of different materials for the electronics industry.

2. Technical Parameters to Consider:

2.1. Laser Power:

- The laser power determines the thickness of the material that can be cut.

- The higher the power, the thicker the material that can be cut.

- Examples:

- To cut 5mm thick carbon steel tubes, you would need at least a 1kW fiber laser cutting machine.

- To cut 2mm thick aluminum tubes, a 500W CO2 laser cutting machine would be sufficient.

2.2. Laser Type:

- The choice of laser type will depend on the material to be cut and the budget.

- Recommendation:

- If you need to cut thick materials like carbon steel or stainless steel, a fiber laser cutting machine is the best option.

- If you need to cut thin materials like aluminum or acrylic, a CO2 laser cutting machine may be sufficient.

- If you need flexibility to cut a wide range of materials, a hybrid laser cutting machine may be the best investment.

2.3. Cutting Precision:

- Cutting precision is important to ensure that cuts are clean and precise.

- Factors that influence:

- The type of laser and the quality of the machine influence the cutting precision.

- For applications that require high precision, such as the manufacture of parts for the aerospace industry, it is important to choose a high-quality machine.

2.4. Cutting Speed:

- The cutting speed determines how quickly the machine can cut the material.

2.5. Working Area:

- The working area determines the size of the tubes that can be cut with the machine.

- Considerations:

- The size of the tubes you need to cut will determine the working area you need.

- If you need to cut large tubes, it is important to choose a machine with a large working area.

2.6. Control Software:

- The control software is what allows you to control the machine and program the cuts.

- Factors to consider:

- The ease of use of the software.

- The features and functionalities of the software.

- The compatibility of the software with your operating system.

2.7. Price:

- The price of tube laser cutting machines varies depending on the type of machine, laser power, working area and other features.

- Recommendation:

- It is important to set a budget before you start looking for a machine.

- Don’t forget to take into account the cost of maintenance and operating costs.

3. Manufacturers and Suppliers:

- There is a wide variety of manufacturers and suppliers of tube laser cutting machines on the market.

- Recommendations:

- It is important to research and compare different manufacturers before making a decision.

- Look for a manufacturer with a good reputation and that offers good customer service.

- Request quotes from several suppliers to compare prices and features.

4. Additional Considerations:

- Warranty:

- It is important to choose a machine with a good warranty.

- The warranty will protect you in case the machine has any problems.

- Training:

- It is important that the personnel who will use the machine receive adequate training.

- Training will help you get the most out of the machine and avoid accidents.

- Technical Service:

- It is important to choose a supplier that offers good technical service.

- Technical service will help you solve any problems you may have with the machine.

5. Conclusion:

Choosing the best tube laser cutting machine for your business depends on a number of factors, such as the type of material you need to cut, the budget you have available, and the features you need.

Recommendations:

- Research and compare different machine models before making a decision.

- Request quotes from several suppliers to compare prices and features.

- Choose a manufacturer with a good reputation and that offers good customer service.

- Make sure that the personnel who will use the machine receive adequate training.

Additional Resources:

- Association of European Manufacturers of Machine Tools: https://www.afm.es/en/about-afm

- European Laser Association: http://www.europeanlaserassociation.com/

- Tube Laser Cutting Machine Manufacturers: https://www.thomasnet.com/products/laser-tube-cutting-96147111-1.html

Latest news in Laser Cutters.

Complete catalog of Laser Cutters.

Preguntas Frecuentes

Los diferentes modelos de audífonos inalámbricos de Apple incluyen los AirPods, los AirPods Pro y los AirPods Max. Cada modelo tiene sus propias características y capacidades únicas.

Los AirPods son los auriculares inalámbricos estándar de Apple. Los AirPods Pro ofrecen características adicionales como cancelación activa de ruido y un ajuste más seguro. Los AirPods Max son auriculares over-ear de alta calidad con cancelación activa de ruido y una experiencia auditiva premium.

Para emparejar tus AirPods con un dispositivo iOS, simplemente abre la caja de los AirPods cerca del dispositivo y sigue las instrucciones en la pantalla. Para emparejarlos con una Mac, ve a Preferencias del Sistema > Bluetooth y selecciona tus AirPods en la lista de dispositivos disponibles.

La duración de la batería de los AirPods puede variar según el modelo y el uso, pero por lo general, ofrecen varias horas de reproducción de audio con una sola carga. Los estuches de carga también pueden proporcionar múltiples cargas adicionales.

Los AirPods de primera y segunda generación no están clasificados como resistentes al agua ni al sudor, por lo que se deben tener precauciones al usarlos durante actividades que impliquen sudor o exposición al agua. Los AirPods Pro, en cambio, tienen una clasificación IPX4, lo que significa que son resistentes al agua y al sudor en cierta medida. Sin embargo, no se recomienda sumergirlos en agua.