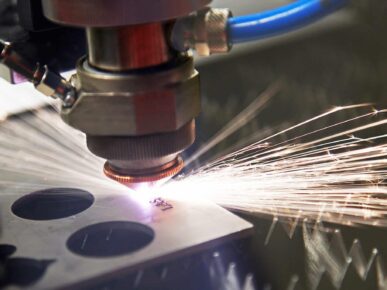

The Best Brands of Laser Cutters

Next we are going to see which are the 5 most popular brands of laser cutters, both by experts and users.

Epilog Laser is renowned for its industry reputation due to its durability and build quality. Their machines are designed for a variety of applications, from small-scale engraving to industrial cutting. Epilog offers an intuitive user interface and reliable technical support, making it a popular choice for both small businesses and large industries.

Characteristics

● Laser Technology: Epilog Laser systems use CO2 laser technology to perform precise cuts and engravings on various materials, including wood, acrylic, plastic, glass, and coated metals.

● Working Area: They come in different working area sizes to suit various needs, ranging from compact desktop models to industrial systems with larger working areas for large-scale production applications.

● Laser Power: Epilog Laser offers models with different laser powers, allowing cutting and engraving of materials with varying thicknesses and densities.

● Speed and Precision: These machines are designed to provide fast and accurate cuts and engravings, making them suitable for applications that require high precision and quality.

● Cooling and Smoke Extraction: Epilog Laser systems typically feature cooling systems to maintain laser temperature and smoke extraction systems to remove residues and gases produced during the cutting or engraving process.

● File Format Compatibility: They can work with a variety of file formats, including vector files (such as .ai and .eps) and image files (such as .jpg and .png), providing flexibility in terms of design.

● Customization Options: Epilog Laser often offers customization options, such as the ability to add accessories like rotary devices for engraving cylindrical objects.

Trumpf is a globally renowned German company specializing in laser technology and manufacturing systems. They offer a wide range of laser cutters, from compact machines to high-end industrial systems. Trumpf’s products are known for their quality, precision, and durability. In addition to laser cutters, Trumpf provides comprehensive solutions for the manufacturing industry, including software and technical support services.

Characteristics

● High Precision: Trumpf laser cutters are equipped with high-precision control systems that ensure accurate and detailed cuts on various materials, from metals to plastics and composite materials.

● Speed and Efficiency: These machines offer fast and efficient cutting speeds, making them ideal for high-speed, high-volume production environments.

● Fiber Laser Technology: Many Trumpf models use fiber laser technology, providing higher energy efficiency and improved cutting quality on materials such as stainless steel, aluminum, and brass.

● Automation Features: Trumpf laser cutters often come with advanced automation features, such as automatic loading and unloading systems, optimizing production efficiency and reducing downtime.

● Integrated Software: They are equipped with intuitive control software that allows operators to easily program and control the cutting process, as well as make precise adjustments for different types of materials and thicknesses.

● Cooling and Fume Extraction Systems: Trumpf machines typically include integrated cooling and fume extraction systems to maintain a safe and clean working environment.

● Material Versatility: These laser cutters are capable of cutting a wide range of materials, including ferrous and non-ferrous metals, plastics, wood, and more, making them versatile for various industrial applications.

● Efficient Maintenance: Trumpf designs their machines with a focus on easy maintenance, allowing for efficient servicing to minimize downtime.

Based in Switzerland, Bystronic is recognized for its high-quality and high-performance laser cutting solutions. The company manufactures laser cutting machines widely used in various industries, from automotive to aerospace. Bystronic’s laser cutting systems are designed to be efficient, precise, and versatile, making them a popular choice among manufacturers requiring precise and clean laser cuts.

Characteristics

● Precision and Speed: Bystronic laser cutters are renowned for their high precision in cuts and speed in material processing, making them ideal for applications requiring fine details and efficiency.

● Material Versatility: These cutters are versatile and can cut a wide range of materials, including steel, stainless steel, aluminum, copper, and other metals, as well as non-metallic materials like plastic and wood.

● Fiber Laser Technology: Many Bystronic models use fiber laser technology, offering high energy efficiency and suitability for cutting thin to medium materials.

● Automation: Bystronic laser cutters are often equipped with automatic loading and unloading systems, enabling continuous and efficient operation, especially in high-volume production environments.

● Advanced Software: They come with advanced software allowing precise programming and control of the cutting process, including capabilities for efficient nesting to maximize material usage and reduce waste.

● Cooling and Fume Extraction Systems: They are equipped with cooling systems to maintain optimal laser temperature and fume extraction systems to keep the work area clean and safe.

● Maintenance and Support: Bystronic typically offers high-quality maintenance and technical support services to ensure continuous and reliable performance of their laser cutters.

Mazak Optonics, a division of Japan’s Yamazaki Mazak Corporation, specializes in advanced laser technology. They offer a variety of laser cutters known for their speed and precision. Their laser cutting systems are used in applications ranging from metal sheet cutting to laser engraving and marking. Mazak Optonics is appreciated for its innovation and focus on continuous improvement of its products.

Characteristics

● Advanced Technology: Mazak Optonics laser cutters utilize cutting-edge laser technology to provide precise and efficient cuts on various materials, including metal, plastic, and other non-metallic materials.

● High Speed and Precision: These machines are designed to offer fast cutting speeds and exceptional precision. This is crucial for industrial applications requiring precise cuts on both thin and thick materials.

● Diverse Applications: Mazak Optonics laser cutters are versatile and used in diverse applications, from metal sheet cutting to laser engraving and marking. They can handle a wide range of material thicknesses and types of metal.

● Automation Systems: Many Mazak Optonics models are equipped with advanced automation systems, such as automatic loading and unloading of materials. This increases production efficiency by reducing downtime and improving workflow.

● User-Friendliness: These laser cutters typically feature intuitive and user-friendly interfaces. This allows operators to efficiently control and adjust cutting parameters, resulting in more effective production.

● Maintenance and Technical Support: Mazak Optonics generally offers robust technical support services and high-quality spare parts to keep their machines running optimally. Additionally, they often provide training and assistance for operators.

Amada is a leading Japanese manufacturer of industrial machinery, including laser cutters. Their laser cutters are known for their reliability and efficiency. They offer a wide range of solutions, from high-speed laser cutting machines to specialized fiber laser cutting systems. Amada is also recognized for its commitment to research and development, enabling them to offer cutting-edge technologies to their customers.

Characteristics

● High Precision: Amada laser cutters offer high precision in cuts, crucial for applications requiring meticulous details and high-quality finishes

● Cutting Speed: These machines are known for their rapid cutting speeds, making them ideal for high-volume production environments where efficiency is paramount.

● Fiber Technology: Amada has developed fiber laser cutting machines, utilizing fiber optic laser technology to provide fast and precise cuts on metallic materials, including stainless steel, aluminum, and carbon steel.

● Automated Systems: Amada laser cutters often come equipped with automated systems for efficient loading and unloading of materials, reducing downtime and increasing productivity.

● Advanced Software: These machines are typically equipped with advanced control software that allows operators to program and control cuts with precision, offering optimization features to reduce material wastage.

● Material Versatility: Amada laser cutters can handle a variety of materials, from common metals to more specialized materials, making them versatile for various industrial applications.

● Reliability and Durability: Amada is known for the reliability and durability of its equipment. Their laser cutters are built to withstand wear and maintain consistent performance even in demanding production environments.

The Best Brands of Laser Cutters

You already know the brands best rated by experts and users, what do you think if we see which are the best laser cutters of each one?

This series of laser cutters offers cutting-edge technology and is known for its precision and versatility. Within the Fusion Pro series, there are several models with different work area sizes and laser powers to suit various needs.

Advantages

● Advanced Precision: The Epilog Fusion Pro is renowned for its high precision, enabling detailed cuts and engravings on a variety of materials.

● Integrated Camera System: The integrated camera feature allows precise design alignment and a preview of the work area, enhancing efficiency and accuracy.

● 3D Engraving Technology: The capability to perform 3D engravings adds versatility to the model, allowing stunning three-dimensional effects on various materials.

● Robust Construction: The Epilog Fusion Pro is built with high-quality materials for exceptional durability, ensuring consistent performance over time.

● User-Friendly: The intuitive user interface and automated features make this model easy to use even for beginners, reducing the learning curve.

● Wide Range of Materials: It can cut and engrave a broad array of materials, from wood and acrylic to coated metals and textiles, making it suitable for diverse applications.

Disadvantages

● Initial Cost: The Epilog Fusion Pro is a high-end device, resulting in a significant initial cost compared to more basic models.

● Size and Weight: Due to its robustness and capability, this model can be large and heavy, which might pose a challenge if workspace is limited.

● Requires Regular Maintenance: Like any laser equipment, the Epilog Fusion Pro requires regular maintenance to ensure optimal performance, which can involve additional costs and time.

● Consumables and Spare Parts: Some specific consumables and spare parts can be expensive and might require special orders, potentially leading to downtime if not managed properly.

● Requires Technical Knowledge: Despite its user-friendly interface, achieving the best results with the Epilog Fusion Pro might require certain technical knowledge, especially for advanced setups and specific adjustments.

This laser cutter series offers a blend of precision, speed, and versatility. TruLaser 3000 series models are designed to handle a wide range of materials, from common metals to special alloys. These machines are known for their ability to cut and engrave with high precision even on thick materials, making them ideal for demanding industrial and commercial applications.

Advantages

● High Precision: The TruLaser 3000 series offers exceptional precision in cuts, allowing for the production of intricate and complex parts with clean and well-defined edges.

● Cutting Speed: These laser cutters are fast and efficient, ensuring rapid production and high performance in industrial and commercial environments.

● Material Versatility: They can handle a wide range of materials, from common metals like steel and aluminum to non-metallic materials such as acrylic and wood, making them versatile for various applications.

● Fiber Optic Technology: Some models in the TruLaser 3000 series utilize fiber optic technology for even more precise and rapid cutting in metallic materials.

● Automation Systems: These machines are often equipped with automation systems for efficient material loading and unloading, increasing productivity and reducing downtime.

● Advanced Software: They come with advanced software that allows precise control and efficient programming, facilitating the creation of complex and customized designs.

Disadvantages

● Initial Cost: The initial acquisition cost can be high, which might be a barrier for small businesses or workshops with limited budgets.

● Requires Regular Maintenance: Like any laser equipment, TruLaser 3000 series laser cutters require regular maintenance to maintain their precision and efficiency, which can involve additional costs.

● Space Requirement: Given their dimensions, these machines can occupy a lot of space, which can be a challenge in smaller working environments.

● Consumables and Spare Parts: Some specific consumables and spare parts can be costly and might require special orders, potentially leading to downtime if not managed properly.

● Learning Curve: To fully leverage all the features and capabilities of these machines, operators might need time to fully familiarize themselves with the software and functionalities, which can take time.

Bystronic ByStar Fiber

The Bystronic ByStar Fiber is a fiber laser cutting machine that combines speed and precision. It is equipped with fiber optic technology, allowing for fast and precise cutting across a variety of materials, including stainless steel, aluminum, and carbon steel. The ByStar Fiber model typically offers high cutting speeds and excellent cut quality, making it a popular choice for industrial applications that require efficiency and precision.

Advantages

● High Cutting Speed: The Bystronic ByStar Fiber is known for its fast cutting speed, increasing efficiency and productivity in industrial environments.

● Excellent Cut Quality: It offers superior cut quality, providing clean and precise edges on a variety of materials, including delicate metals.

● Material Versatility: It can cut a wide range of materials, from stainless steel to aluminum and brass, making it suitable for various industrial applications.

● Fiber Optic Technology: Equipped with fiber optic technology, the ByStar Fiber allows fast and precise cuts, even on thick materials, with lower energy consumption.

● Energy Efficiency: Fiber laser cutters are often more energy-efficient compared to CO2 laser cutting machines, potentially resulting in lower long-term operating costs.

Disadvantages

● High Initial Cost: The initial price of the Bystronic ByStar Fiber can be considerably high, representing a significant investment for small businesses or workshops.

● Requires Specialized Maintenance: Being a high-tech machine, it may require specialized maintenance and costly spare parts, increasing operational costs over time.

● Space Requirements: Due to its robustness and capacity, the ByStar Fiber can be large and heavy, which can be a challenge if workspace is limited.

● Downtime for Maintenance: During maintenance operations, the machine may be out of service, potentially affecting production if not properly planned.

● Learning Curve: To fully leverage the capabilities of this machine, operators may require a learning period to fully grasp its features and functionalities.

Mazak Optiplex Nexus Fiber

The Mazak Optiplex Nexus Fiber is a high-end laser cutter known for its exceptional precision, speed and versatility in cutting metal materials. Designed for demanding industrial and commercial applications, this machine represents the latest in laser cutting technology.

Advantages

● High Precision: Offers extremely precise cuts on a variety of metal materials, ensuring high-quality results in detailed and complex applications.

● Cutting Speed: Utilizes fiber laser technology to provide fast cutting speeds, improving efficiency and reducing production times.

● Material Versatility: Can cut a wide range of metal materials, including stainless steel, aluminum, and titanium, making it suitable for various industrial applications.

● Energy Efficiency: Fiber laser technology is more energy-efficient, reducing operating costs and environmental impact.

● Intuitive User Interface: Comes with a user-friendly interface that allows operators to program and monitor cutting operations easily and efficiently.

● Optimization Features: Includes automatic optimization features that minimize material waste and enhance cutting efficiency.

Disadvantages

● High Initial Cost: As a high-end laser cutter, the Mazak Optiplex Nexus Fiber can have a significantly high initial price, which might be beyond the reach of small businesses or workshops with limited budgets.

● Specific Knowledge Required: To fully utilize its capabilities, it may require specific technical knowledge, which can steepen the learning curve for new users.

● Maintenance Costs: Maintenance costs, especially for specific components or spare parts, can be high, increasing long-term operational expenses.

● Space Requirement: Given its size and capacity, the Mazak Optiplex Nexus Fiber can occupy a considerable space in the workshop, which can be a limitation for facilities with limited space.

● Dependency on Environmental Conditions: Like all laser cutters, its performance can be influenced by environmental conditions, such as temperature and humidity, requiring careful control of the working environment.

Amada FOL-3015 AJ Fiber Laser Cutting System

The Amada FOL-3015 AJ is a high-end fiber laser cutting system designed to deliver outstanding performance in industrial and production applications. This laser cutter represents cutting-edge technology, taking precision and efficiency to the next level.

Advantages

● High Precision: It offers precise and detailed cuts on a wide variety of metallic materials, ensuring the quality and integrity of the cut pieces.

● High Cutting Speed: Provides fast and efficient cutting speeds, increasing productivity in high-volume industrial environments.

● Fiber Optic Technology: Uses fiber optic laser technology, offering higher speed and greater energy efficiency compared to other types of lasers.

● Advanced Control System: Equipped with an easy-to-use and highly accurate control system, allowing operators to program complex cuts with ease.

● Material Versatility: Can cut a wide range of materials, from stainless steel to aluminum and coated metals, making it versatile for various industrial applications.

● Simplified Maintenance: Designed to require minimal maintenance, reducing downtime and ensuring higher availability for production.

Disadvantages

● High Initial Cost: High-quality, high-performance equipment often comes with a significant initial cost, which can be a barrier for small businesses or workshops with limited budgets.

● Space Requirement: Due to its size and capacity, it requires considerable floor space, which can be a challenge in smaller work environments.

● Need for Training: To fully utilize all its features, operators might require specific training, which can require additional time and resources.

● Expensive Consumables: Some specific consumables, such as lenses and nozzles, can be costly and need to be replaced periodically, increasing long-term operational costs.

● Complexity for Small Applications: It might be too advanced and costly for small and straightforward cutting applications, where a more basic model could be more suitable and cost-effective.

● Initial Setup Time: Properly setting up and calibrating the equipment can take time, especially for users with no prior experience in laser cutters.