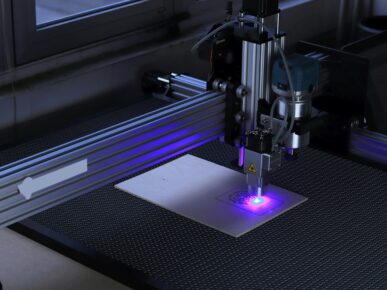

The best CO2 laser cutter.

Best CO2 laser cutter

According to our analysis, the best laser cutter with CO2 technology is the Epilog Zing

How have we made this comparison of laser cutters?

In our laser cutter comparison, we follow a meticulous process:

- Initial Research: We identify popular models through reviews and expert.

- opinions. Diverse Selection: We choose models representing various features, such as price, type, and key functions.

- Evaluation Criteria: We define criteria such as cutting quality, convenience, and durability for each model.

- Practical Testing: We conduct hands-on tests, including cutting sessions and evaluation of special features.

- Comparative Analysis: We compile results into a detailed comparison based on objective data and practical experience.

- User and Expert Opinions: We incorporate real user feedback and expert evaluations to provide a comprehensive perspective.

- Periodic Updates: Committed to regularly updating the comparison to reflect changes in the market.

Our goal is to provide you with accurate and up-to-date information, helping you make informed decisions when choosing your ideal laser cutter.

Analysis of the best laser cutter with CO2 technology

Click on the images below to read our reviews of the best CO2 laser cutters on the market.

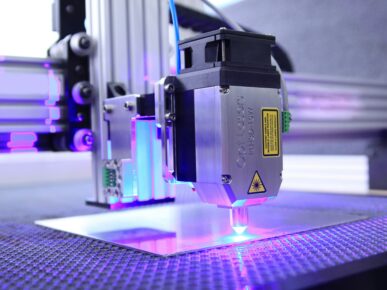

The Best Laser Cutter with CO2 Technology Value for Money: Epilog Zing

PROS

🟢 Material Versatility: CO2 laser cutters, including the Epilog Zing, are known for their versatility in cutting a variety of materials such as wood, acrylic, and fabric.

🟢 Ease of Use: Many Epilog laser cutters, including the Zing, are praised for their user-friendly interface that is easy to learn.

🟢 Intuitive Software: The Epilog Zing typically comes with intuitive software that facilitates the design and execution of projects.

🟢 Brand Reputation: Epilog Laser has a solid reputation in the industry, instilling confidence in the product’s quality and support.

🟢 Cutting Quality: They offer high cutting quality and fine details, making them ideal for engraving and precision cutting applications.

CONS

🔴 Initial Cost: CO2 laser cutters, in general, may have a significant initial cost, which could be a drawback for some users.

🔴 Maintenance Required: They may require regular maintenance and care to ensure optimal performance.

🔴 Limited Working Area: Depending on the specific model, the Epilog Zing and other laser cutters may have a limited working area, which could be a restriction for larger projects.

🔴 Cutting Speed: Compared to some cutting technologies, the cutting speed of CO2 laser cutters may be relatively slower in certain cases.

🔴 Requires Ventilation and Extraction: Most CO2 laser cutters need proper ventilation and extraction systems to handle cutting byproducts, which could require additional installations.

Read our full review of the Epilog Zing laser cutter.

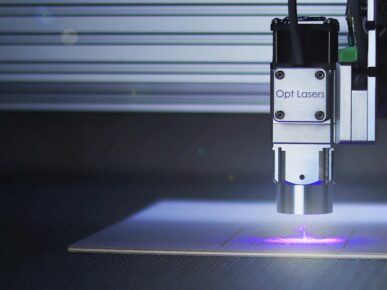

Guide to choosing the best laser cutter with CO2 technology.

1. Define Your Needs:

- Clearly specify the purpose of the laser cutter. Is it for hobby projects, entrepreneurship, or industrial production? This will influence the type of features and capabilities you require.

2. Initial Research:

- Investigate leading brands and models of CO2 laser cutters. Read online reviews, participate in user forums, and consult industry experts for insights into the reliability and performance of different models.

3. Materials to Cut:

- Consider the materials you plan to cut frequently. While CO2 laser cutters are versatile, some models may be more efficient with certain materials. Ensure that the machine is compatible with the materials you need to cut.

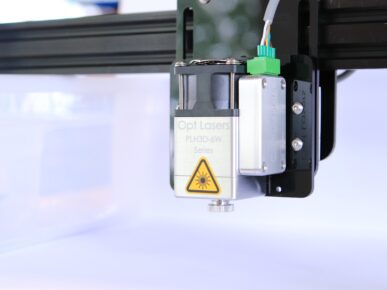

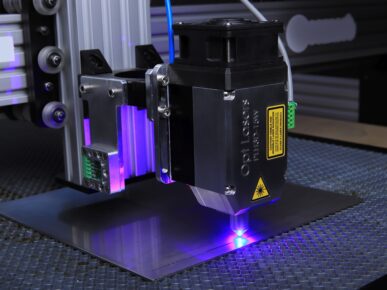

4. Laser Power:

- Evaluate the laser power in watts. For cutting thicker or denser materials, you will need higher power. If the machine will also be used for detailed engravings, look for a balance between power and precision.

5. Working Area and Machine Size:

- Determine the size of the working area you need based on your typical projects. Ensure that the laser cutter fits within the available space in your workshop.

6. Control Software:

- Verify the quality and functionality of the laser cutter’s control software. Intuitive software will make designing and executing projects easier. Additionally, ensure compatibility with the file formats you plan to use.

7. Cutting Speed and Acceleration:

- Understand the cutting speed and acceleration capabilities of the machine. These factors will impact efficiency and the speed at which you can complete your projects.

8. Precision and Resolution:

- Check the precision of the laser cutter, especially if you are involved in work requiring fine details and meticulous engravings.

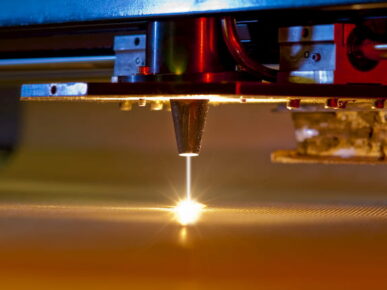

9. Extraction and Ventilation System:

- Ensure that the laser cutter has an efficient extraction system to remove smoke and particles during cutting. Proper ventilation is essential for maintaining a safe working environment.

10. Additional Features and Accessories: – Consider additional features such as 3D engraving, automatic focus, and the ability to rotate the laser head. Also, check the availability and variety of accessories to customize the machine to your specific needs.

11. Build Quality: – Examine the quality of materials used in constructing the machine. A sturdy and durable structure contributes to the stability and longevity of the laser cutter.

12. Consumables and Operating Costs: – Research the cost and availability of consumables such as lenses and laser tubes. Also, consider operating costs over time to get a realistic estimate of the total cost of ownership.

13. Brand Reputation and Technical Support: – Choose brands with a good reputation and a proven track record in providing quality laser cutters. Ensure they offer solid technical support and customer service.

14. Warranty and After-Sales Service: – Verify warranty options and after-sales service provided by the manufacturer. A good warranty can provide peace of mind and protection against potential issues.

15. Safety Certifications: – Ensure that the laser cutter complies with safety regulations and possesses necessary certifications. Safety in using the machine is of utmost importance.

16. User Reviews and Feedback: – Read multiple reviews from real users about the model you are considering. Other users’ experiences can offer valuable insights into the performance and reliability of the laser cutter.

17. Updates and Future Expansions: – Investigate if the laser cutter has upgrade options and if the manufacturer offers future expansions to keep your machine up-to-date with the latest technologies.

By following these steps and considerations, you can make an informed choice when selecting a CO2 laser cutter that fits your specific needs and expectations. Keep in mind that technology and models may change over time, so stay updated with the latest market developments.

Latest news in Laser Cutters.

Complete catalog of Laser Cutters.

Preguntas Frecuentes

Los diferentes modelos de audífonos inalámbricos de Apple incluyen los AirPods, los AirPods Pro y los AirPods Max. Cada modelo tiene sus propias características y capacidades únicas.

Los AirPods son los auriculares inalámbricos estándar de Apple. Los AirPods Pro ofrecen características adicionales como cancelación activa de ruido y un ajuste más seguro. Los AirPods Max son auriculares over-ear de alta calidad con cancelación activa de ruido y una experiencia auditiva premium.

Para emparejar tus AirPods con un dispositivo iOS, simplemente abre la caja de los AirPods cerca del dispositivo y sigue las instrucciones en la pantalla. Para emparejarlos con una Mac, ve a Preferencias del Sistema > Bluetooth y selecciona tus AirPods en la lista de dispositivos disponibles.

La duración de la batería de los AirPods puede variar según el modelo y el uso, pero por lo general, ofrecen varias horas de reproducción de audio con una sola carga. Los estuches de carga también pueden proporcionar múltiples cargas adicionales.

Los AirPods de primera y segunda generación no están clasificados como resistentes al agua ni al sudor, por lo que se deben tener precauciones al usarlos durante actividades que impliquen sudor o exposición al agua. Los AirPods Pro, en cambio, tienen una clasificación IPX4, lo que significa que son resistentes al agua y al sudor en cierta medida. Sin embargo, no se recomienda sumergirlos en agua.