The best fiber Laser Cutter.

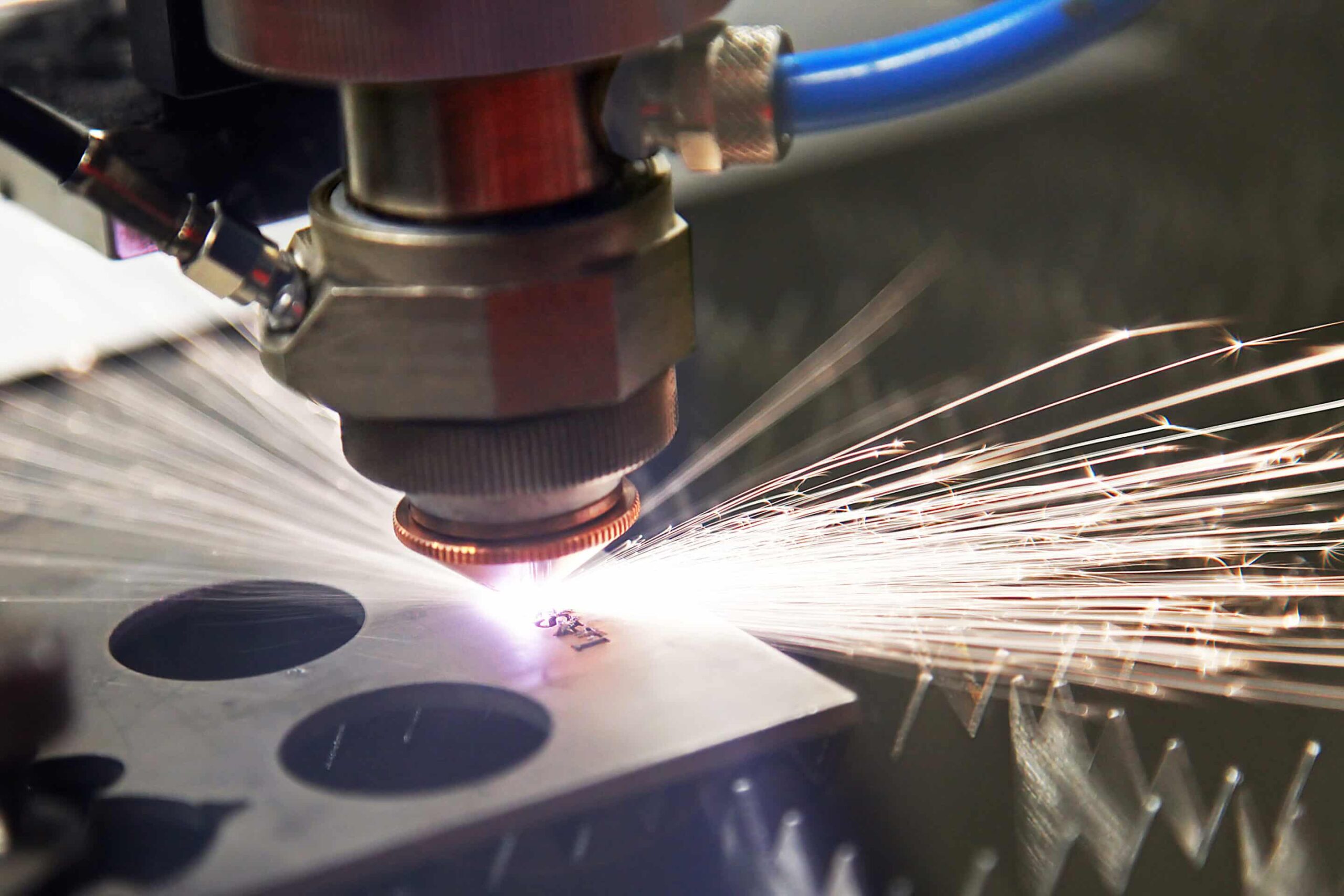

Best Fiber Laser Cutter

According to our analysis, the best fiber Laser Cutters is the Bystronic BySprint Fiber

How have we made this comparison of laser cutters?

In our laser cutter comparison, we follow a meticulous process:

- Initial Research: We identify popular models through reviews and expert.

- opinions. Diverse Selection: We choose models representing various features, such as price, type, and key functions.

- Evaluation Criteria: We define criteria such as cutting quality, convenience, and durability for each model.

- Practical Testing: We conduct hands-on tests, including cutting sessions and evaluation of special features.

- Comparative Analysis: We compile results into a detailed comparison based on objective data and practical experience.

- User and Expert Opinions: We incorporate real user feedback and expert evaluations to provide a comprehensive perspective.

- Periodic Updates: Committed to regularly updating the comparison to reflect changes in the market.

Our goal is to provide you with accurate and up-to-date information, helping you make informed decisions when choosing your ideal laser cutter.

Analysis of the best fiber Laser Cutters

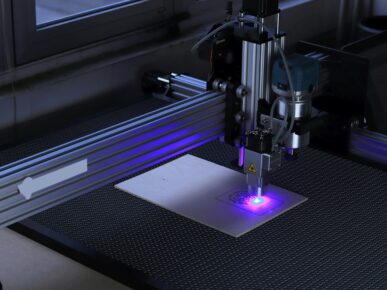

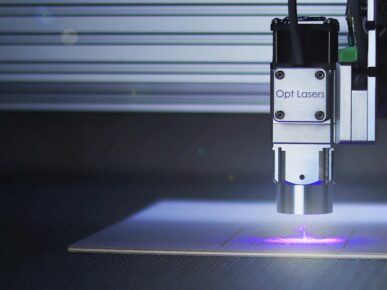

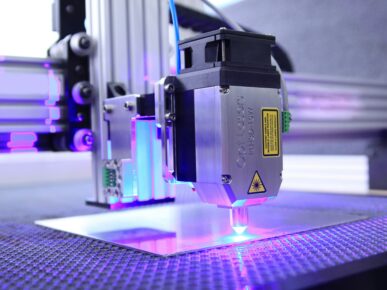

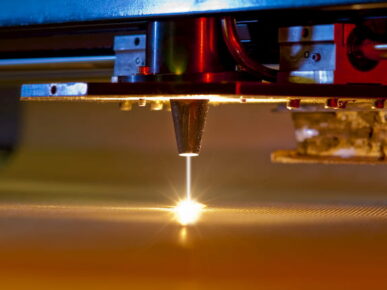

Click on the images below to read our reviews of the best Fiber laser cutters on the market.

The Best Fiber Laser Cutters Value for Money: Bystronic BySprint Fiber

PROS

CONS

Read our full review of the Bystronic BySprint Fiber.

Choosing the Best Fiber Laser Cutter: A Comprehensive Guide to Decision-Making

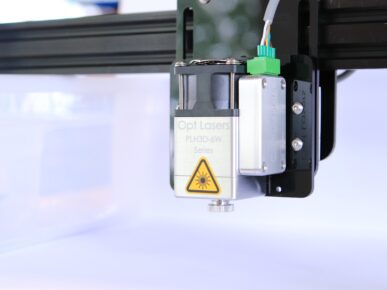

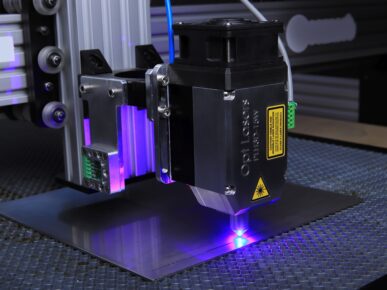

Fiber laser cutters have revolutionized the cutting industry, offering an exceptional balance between speed and precision. Amidst the variety of options available, making the right decision on the best fiber laser cutter for your specific needs is crucial. In this detailed guide, we will delve even deeper into key features and provide additional information to ensure an informed choice.

1. Speed and Precision:

Speed and precision are cornerstones of production efficiency. When considering cutting speed, observe not only the theoretical maximum speed but also how this speed can be maintained under normal usage conditions. Additionally, precision refers not only to precise cutting but also to repeatability and consistency over time.

2. Material Type and Application Variety:

Versatility in the type of material a laser cutter can handle is crucial. While some excel in metals, others can cut non-metallic materials such as plastics and woods. Evaluate your specific needs and consider if the selected machine can adapt to a variety of applications to meet your future requirements.

3. Power Consumption and Sustainability:

Energy efficiency not only impacts operating costs but also the environmental footprint. When choosing a fiber laser cutter, consider its energy consumption in relation to its performance. More efficient machines are not only economically beneficial but also contribute to environmental sustainability.

4. Maintenance, Reliability, and Downtime:

Regular maintenance is essential for the continuous performance of a laser cutter. Assess the ease of maintenance and the frequency of potential downtimes. Machines that require less downtime for maintenance can significantly increase productivity.

5. Initial Cost vs. Long-Term Performance:

While the initial cost may be a deciding factor, it’s essential to consider the long-term return on investment. More expensive machines often offer advanced features, greater durability, and efficiency, resulting in significant savings and benefits over time.

6. Manufacturer Reputation and Customer Service:

The manufacturer’s reputation is a key indicator of product quality and the level of customer service. Research the manufacturer’s track record, read reviews and testimonials, and consider the availability and quality of technical support.

7. Additional Features and Automation:

Additional features such as quick tool-change systems, automatic processing capabilities, and compatibility with advanced software can significantly enhance efficiency and user-friendliness. Automation can also be key to increasing productivity and reducing dependence on specialized skills.

8. Machine Size and Installation Requirements:

Consider the available space in your workshop and the installation requirements of each laser cutter. Ensure that the chosen machine fits comfortably into the working environment and complies with power and environmental stability requirements.

9. Software Integration and Connectivity:

The ability of the fiber laser cutter to integrate with design software and computer-aided manufacturing (CAM) systems can make a difference in operational efficiency. Compatibility with standard file formats and the ability to communicate with other equipment in the workshop are important aspects to consider.

10. Advanced Cutting Capabilities:

Research the specific cutting capabilities of each model. Some fiber laser cutters can perform three-dimensional, beveled, or laser marking cuts. These aspects can open up opportunities for more complex and customized applications, crucial for certain types of production.

11. Future Needs Assessment:

Before making a decision, consider how your needs might evolve in the future. Investing in a fiber laser cutter that can adapt to changes in market demand or product diversification will ensure that your machinery remains relevant and productive in the long term.

12. Comparative Evaluation with Competing Models:

Conduct a detailed comparison between the Bystronic BySprint Fiber and other leading models in the market. Consider technical specifications, user reviews, and unique features offered by each machine. This direct comparison can reveal key differences and aid in decision-making.

13. Environmental Considerations:

Evaluate the environmental impact of each fiber laser cutter. Some models may incorporate eco-friendly features or adhere to stringent environmental standards. Considering the ecological footprint can align your business with sustainable practices and may have positive implications for corporate responsibility.

14. Industry-Specific Requirements:

Different industries may have unique demands when it comes to laser cutting. Investigate whether the Bystronic BySprint Fiber or other models cater to specific industry needs, such as automotive, aerospace, or electronics. Choosing a laser cutter designed for your industry can result in optimized performance.

15. User-Friendliness and Training:

Examine the user interface and overall user experience offered by each laser cutter. A machine with an intuitive interface and user-friendly features can reduce the learning curve for operators. Additionally, assess the availability of training resources and customer support to ensure seamless integration into your workflow.

16. Warranty and Support:

Carefully review the warranty terms and post-purchase support provided by the manufacturer. A comprehensive warranty and reliable customer support can provide peace of mind and minimize potential disruptions in case of technical issues. Consider extended warranty options for added protection.

17. Market Trends and Technological Advancements:

Stay informed about current market trends and the latest technological advancements in fiber laser cutting. While the Bystronic BySprint Fiber may currently meet your requirements, understanding emerging technologies can help future-proof your investment and ensure long-term relevance in a rapidly evolving industry.

18. Customization Options:

Explore the level of customization offered by each model. The ability to tailor the laser cutter to specific requirements can be advantageous, especially if your production processes have unique demands that require personalized solutions.

19. International Standards Compliance:

Check if the laser cutter complies with international safety and quality standards. Adherence to standards such as ISO and CE ensures that the machine meets established benchmarks for performance, safety, and reliability.

20. Real-World User Feedback:

Seek feedback from actual users of the Bystronic BySprint Fiber and other considered models. Real-world experiences can provide valuable insights into the day-to-day usability, durability, and performance of the machines. Online forums, industry events, and networking can be valuable resources for gathering user feedback.

Conclusion:

In conclusion, the decision to choose the best fiber laser cutter involves a comprehensive evaluation of numerous factors. From speed and precision to environmental considerations and real-world user feedback, each aspect plays a crucial role in determining the suitability of the machine for your specific needs. Take the time to thoroughly research, compare, and consider both current and future requirements. By doing so, you can make an informed decision that aligns with your production goals and positions your business for success in the dynamic field of laser cutting.

Latest news in Laser Cutters.

Complete catalog of Laser Cutters.

Preguntas Frecuentes

Los diferentes modelos de audífonos inalámbricos de Apple incluyen los AirPods, los AirPods Pro y los AirPods Max. Cada modelo tiene sus propias características y capacidades únicas.

Los AirPods son los auriculares inalámbricos estándar de Apple. Los AirPods Pro ofrecen características adicionales como cancelación activa de ruido y un ajuste más seguro. Los AirPods Max son auriculares over-ear de alta calidad con cancelación activa de ruido y una experiencia auditiva premium.

Para emparejar tus AirPods con un dispositivo iOS, simplemente abre la caja de los AirPods cerca del dispositivo y sigue las instrucciones en la pantalla. Para emparejarlos con una Mac, ve a Preferencias del Sistema > Bluetooth y selecciona tus AirPods en la lista de dispositivos disponibles.

La duración de la batería de los AirPods puede variar según el modelo y el uso, pero por lo general, ofrecen varias horas de reproducción de audio con una sola carga. Los estuches de carga también pueden proporcionar múltiples cargas adicionales.

Los AirPods de primera y segunda generación no están clasificados como resistentes al agua ni al sudor, por lo que se deben tener precauciones al usarlos durante actividades que impliquen sudor o exposición al agua. Los AirPods Pro, en cambio, tienen una clasificación IPX4, lo que significa que son resistentes al agua y al sudor en cierta medida. Sin embargo, no se recomienda sumergirlos en agua.