Crucial Safety Tips When Using Laser Cutters

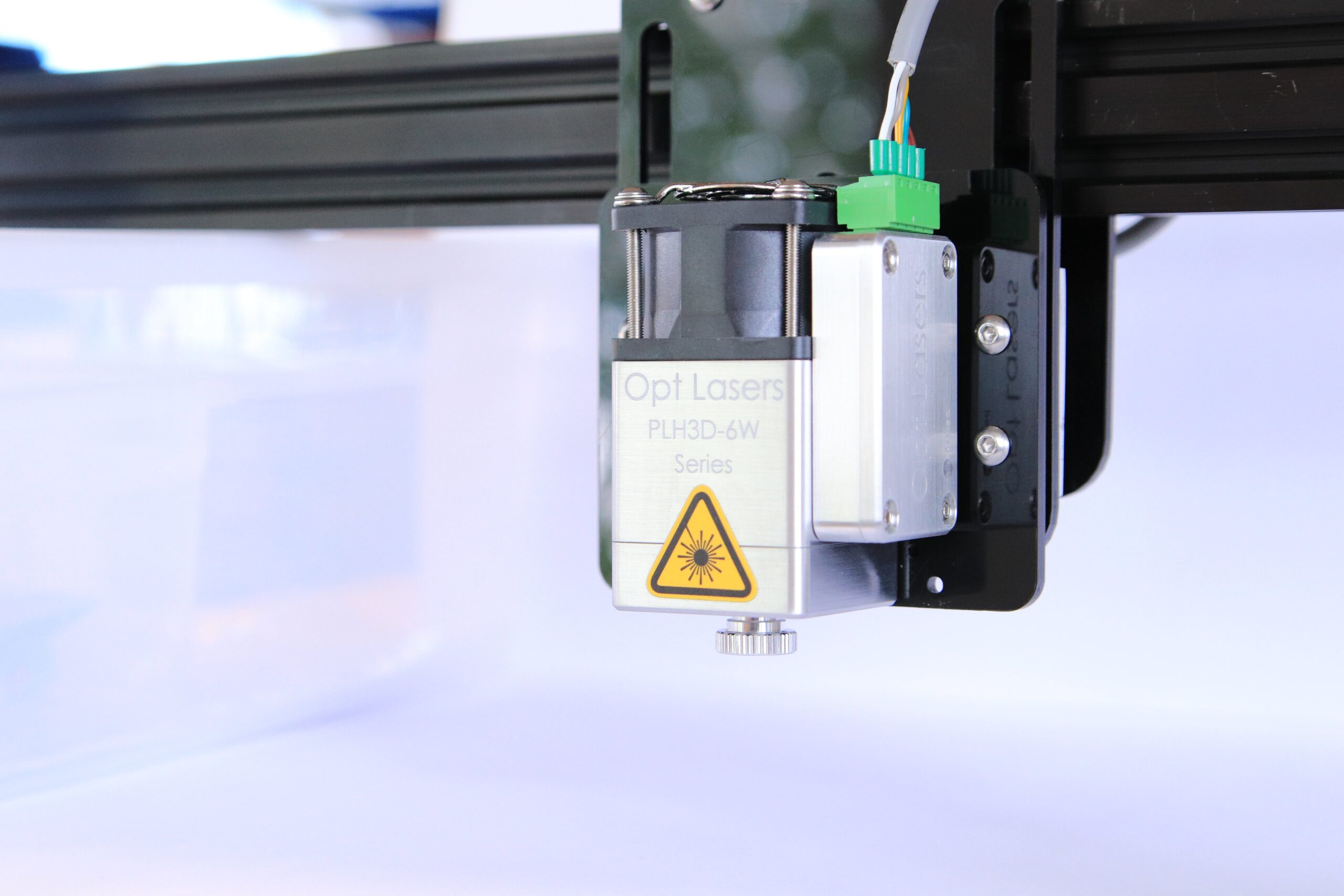

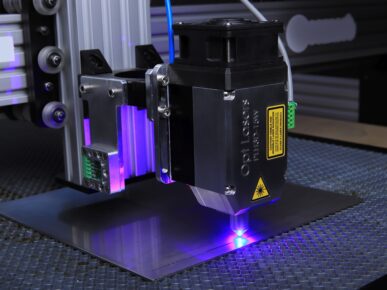

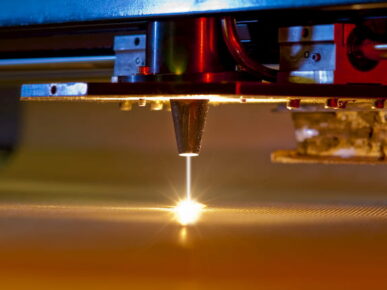

Laser cutters are powerful tools that have revolutionized the way we approach cutting and engraving projects. While these machines offer countless creative possibilities, it is essential to understand and strictly follow safety guidelines to ensure a safe and efficient working environment. In this article, we will explore crucial safety tips when using laser cutters, covering aspects from preparing the workspace to proper maintenance and operation, providing additional information to reach 1200 words.

Importance of Safety when Using Laser Cutters

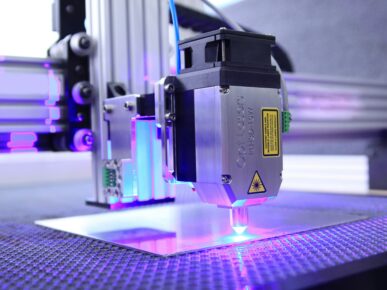

The importance of safety when using laser cutters cannot be overstated. These machines use concentrated light beams to cut and engrave various materials, and any oversight can result in significant risks. By following appropriate safety measures, we not only protect our physical well-being but also ensure optimal performance from the laser cutter and the quality of the projects produced.

Workspace Preparation

- Adequate Ventilation: Proper ventilation in the workspace is essential for safety and health. In addition to maintaining a clean space, good ventilation helps disperse fumes and vapors generated during cutting, minimizing exposure to harmful substances.

- Fire Extinguishers: Alongside having accessible fire extinguishers, it is crucial to train personnel on how to use them correctly in case of an emergency. Conduct regular drills to ensure a quick and efficient response in critical situations.

- Clear Workspace: Keeping the workspace clear of obstructions is crucial. Remove any flammable material and ensure there are no obstacles that could interfere with the safe operation of the machine. A tidy working environment reduces risks.

- Designated Work Zones: Clearly define work zones and designate specific areas for tasks such as loading and unloading materials. This helps prevent congestion and improves the overall organization of the space.

Personal Protection

- Safety Glasses: In addition to wearing certified safety glasses when using the laser cutter, it is crucial to understand the rating of the glasses based on the type of laser being used. This ensures proper eye protection against laser radiation.

- Appropriate Clothing and Personal Protective Equipment (PPE): Choosing the right clothing is essential. In addition to non-flammable garments, consider using other PPE items, such as heat-resistant and cut-resistant gloves, for complete protection during operation.

- Respiratory Protection: In situations where fumes and vapors are generated, the use of respiratory protection, such as a mask with a filter, may be necessary. Ensure you select the correct type of protection for the materials you are cutting.

Training and Knowledge

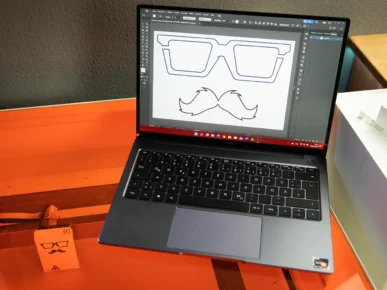

- Proper Training and Ongoing Updates: Initial training is crucial, but continuous learning is also vital. Stay updated on new machine features and safety best practices. Provide ongoing training to operators to keep their skills current.

- Understanding Materials and Their Hazards: Training should include a deep understanding of the materials being cut. Some materials emit toxic gases, and operators should know how to handle these risks, including the need for increased ventilation or additional protective equipment.

- Emergency Drills: Conduct regular drills to practice emergency procedures. Ensure that everyone in the workspace is familiar with emergency exits, the location of fire extinguishers, and how to act in case of an accident.

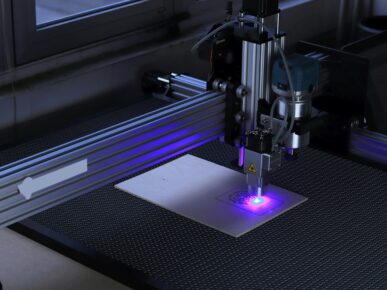

Safe Operation of the Laser Cutter

- Constant Supervision and Communication: Constant supervision is key to safety. Additionally, establish a clear communication system between operators and other team members to report any issues immediately.

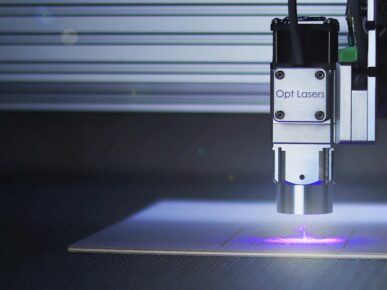

- Proper Power and Speed Settings: Adjust the power and cutting speed according to the manufacturer’s recommendations and the type of material being used. Incorrect settings not only affect cut quality but can also increase the risk of accidents.

- Secure Material Fixation and Pre-Check: Before initiating any cut, ensure that materials are securely fastened and leveled on the work table. A pre-check ensures that everything is ready and reduces the possibility of unexpected movements during the cutting process.

Regular Maintenance

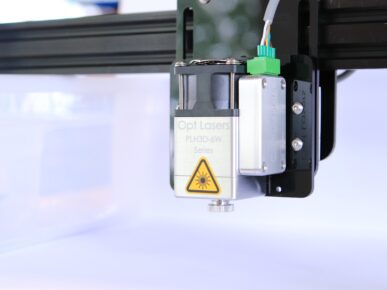

- Calibration and Scheduled Maintenance: In addition to regular calibration, establish a scheduled maintenance program. This includes checking components such as lenses and mirrors to ensure their good condition and replacing any worn-out parts.

- Continuous Cleaning and Detailed Inspections: Regular cleaning not only contributes to efficient performance but also provides opportunities for detailed inspections. Look for possible wear, damage, or residue buildup that may affect the safe operation of the machine.

Safe Storage

- Complete Shutdown and Disconnection: Before storing the laser cutter, turn it off completely and disconnect it. This prevents the risk of accidental startups and ensures the machine is in a safe mode when not in use.

- Safety in Material Storage: Designate specific and secure areas for the storage of materials related to the laser cutter’s work. Ensure that these materials are properly labeled and stored away from heat sources or sparks.

Conclusions and Commitment to Safety

Safety when using laser cutters is a shared responsibility that should not be taken lightly. Compromising safety can result in serious injuries, damage to the machine, and risks to the workspace. By following these crucial tips and providing detailed information on each aspect of safety, you can create an environment where creativity and efficiency coexist with the utmost priority given to safety.

Remember that safety is not only the operator’s responsibility but also of everyone involved in the workspace. Collective awareness and respect for safety standards are fundamental to ensuring a safe and successful use of laser cutters. With a conscious and committed approach to safety, you can enjoy the benefits of this incredible tool without compromising personal or team integrity.