In the era of advanced technology, laser cutters have become essential tools for a variety of industries, from manufacturing to artistic creation. But how do these marvels of modern engineering really work? In this comprehensive review, we will unravel the secrets behind laser cutters and explore their diverse applications.

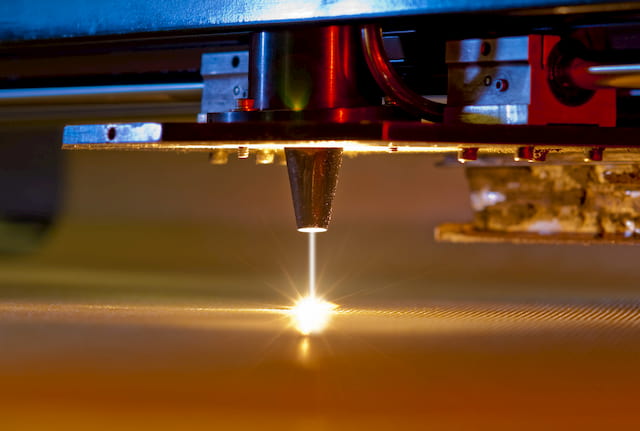

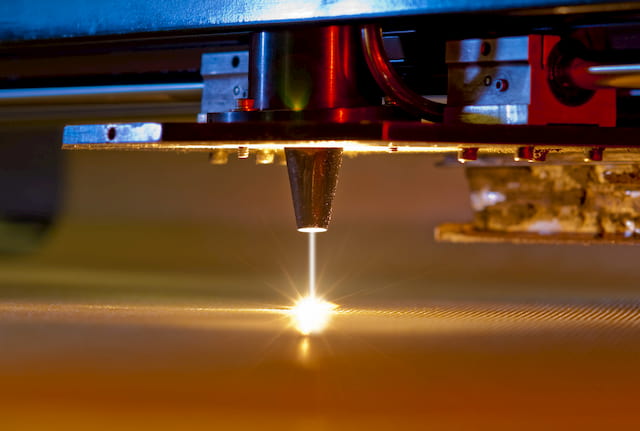

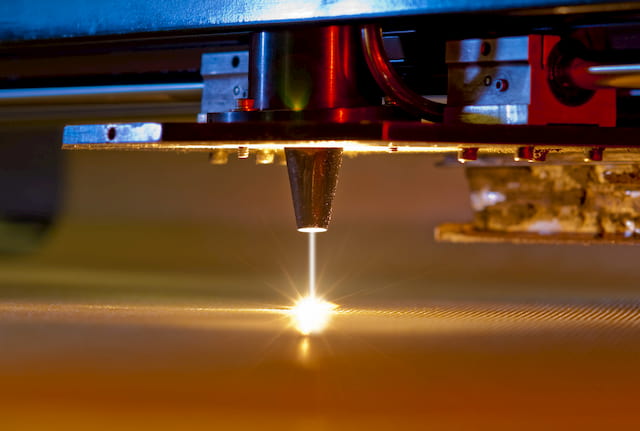

At the core of every laser cutter is laser technology. These devices use a concentrated high-intensity laser beam to cut and engrave materials with millimeter precision. The most commonly used type of laser is the carbon dioxide (CO2) laser or the fiber laser.

The laser beam is directed through a series of mirrors and lenses to properly focus it before reaching the material. This optical system ensures that the laser energy is concentrated at the exact point where it is needed for precise cuts or engravings.

Most laser cutters feature a worktable that provides stability to the material and allows for precise positioning. Some tables are fixed, while others can be adjusted in height to accommodate different material thicknesses.

Computer Numerical Control is essential for the operation of a laser cutter. A Computer-Aided Design (CAD) program specifies the dimensions and shape of the cut, and the CNC translates these instructions to precisely guide the laser’s movement.

CO2 laser cutters are ideal for cutting non-metallic materials such as wood, acrylic, leather, and fabric. Their versatility makes them indispensable in industries ranging from advertising to model making.

For metallic materials, fiber laser cutters are the preferred choice. These use a solid-state laser to provide quick and precise cuts in steel, aluminum, and other metals.

Laser cutters not only cut; they are also experts in engravings and markings. From intricate details in jewelry to product customization, these machines offer a range of creative possibilities.

Each material has its own cutting characteristics. Learning about the optimal speed, power, and frequency for each type of material will ensure optimal results.

Regular maintenance, such as cleaning lenses and mirrors, will ensure that the laser cutter operates efficiently and prolong its lifespan.

The use of personal protective equipment, such as safety glasses, is crucial when working with laser cutters. Safety should be the top priority in any work environment.

In conclusion, laser cutters have revolutionized how we cut, engrave, and mark a variety of materials. Their millimeter precision and versatility make them invaluable tools in a wide range of industries. As technology continues to advance, we are sure to see new innovations that will further expand the applications of these incredible machines.

In your journey to explore laser cutters, keep these fundamental principles and practical tips in mind to make the most of this fascinating technology. May your laser cutting projects always be precise and creative!